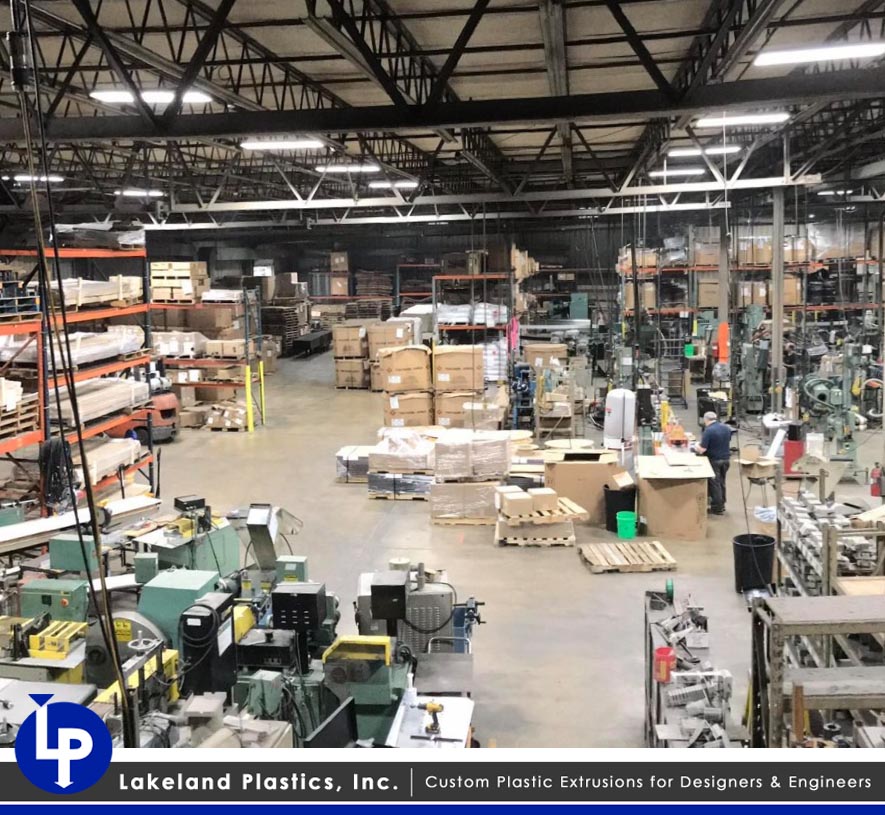

Lakeland Plastics is excited to announce the completion of its new lighting project done with the help of a rebate from ComEd. Lakeland Plastics completely replaced all its high efficiency fluorescent lamps in the production and warehouse areas with super efficient LED Hi Bay lighting from 5K Smart Systems.

Plastic Extrusions for the Lighting Industry

Lakeland Plastics, a custom plastic extrusion company in Mundelein, IL manufactures the lenses for these new LED lights as well as other custom plastic extruded product for the lighting industry.

As a key supplier to the commercial lighting industry for more than 60 years, Lakeland Plastics manufacturers acrylic and polycarbonate lenses for the LED lighting industry as well as other profiles used in various parts of lighting fixtures.

Acrylic has inherently good clarity and will not yellow with exposure to lighting or the elements.

Polycarbonate is an extremely tough material for high impact situations.

Extruded Plastic Lenses for the LED Lighting Industry

Lakeland can extrude LED lenses in clear, translucent, frosted or colors. Our design engineers can assist you in the design of your lens to optimize clarity or diffusion, depending on your specific requirements. Lenses can be smooth or ribbed to aid in diffusion. A specialty blend of frosted acrylic can diffuse light so efficiently that you cannot even see the hot spot created by the LED, resulting in the light fixture emitting a solid bar of light, similar to neon.

Lakeland Plastics was one of the first plastic extrusion companies to utilize frosted acrylic in the creation of LED neon lights.

An important part of Lakeland Plastics commitment to going Green, the new High Efficiency LED lights are expected to use far less electricity while also providing 3 times the foot candles in lighting to the production areas.