Friendly people quick loading and overnight parking if your in a pinch at the dock I’d suggest call ahead

Custom Plastic Extrusions for Designers and Engineers

At Lakeland Plastics, we combine decades of extrusion expertise with advanced 3D printing technology to deliver fast, affordable, and precise prototypes that help bring your designs to life

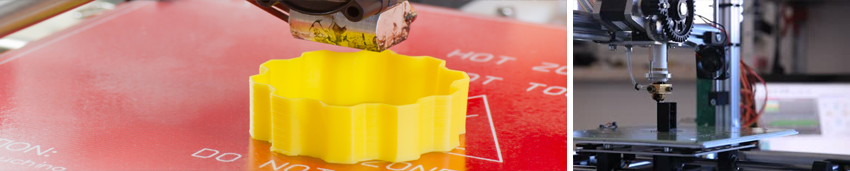

3D printing is a term used to describe a variety of additive manufacturing technologies. These manufacturing technologies produce custom parts by accurately “printing” layer upon layer of plastic until a 3D form is created. Additive manufacturing technologies can quickly create tangible parts that allow individuals to touch, feel, and assess their design.

At Lakeland Plastics, 3D plastic printing gives you a fast and cost-effective way to transform digital CAD files into product samples, prototypes, or proof of concept parts. Whether you’re testing a new concept or refining an existing design, our technology makes it easy to create accurate samples without the need for costly tooling. This process helps accelerate product development while reducing upfront risks.

Our 3D printed extrusion services allow you to experiment with shapes, sizes, and features before committing to production. With the ability to print complex geometries and intricate profiles, Lakeland enables you to evaluate performance, fit, and aesthetics early in the design process. It’s the perfect solution for industries that demand precision prototypes with quick turnaround times.

Durability matters in prototyping, which is why we use ABS plastic to deliver strong, dependable parts. Unlike fragile prototypes, our ABS prints withstand handling and testing while maintaining dimensional accuracy. This gives you a true-to-life model that reflects how your product will perform in full-scale production. And by producing samples in days instead of weeks, we help you streamline decision-making and move projects toward production faster.

Friendly people quick loading and overnight parking if your in a pinch at the dock I’d suggest call ahead

Just delivered. The guy that unloaded me was awesome. In and out in 15 minutes. Give that man a raise!

I met with Lakeland Plastics this week. They were very professional to meet with. They were generous with their time and were helpful educating me on the plastics industry. While we weren’t a fit for each other in this instance , I can tell that anyone looking for extrusions would be in great hands. I appreciate the referrals and care they provided me.

Great company to work with, they hold a high standard of quality in the work they do with great communications!

We initially faced challenges with a product that required one side to be white and the other black. The previous process involved painting one side, which was time-consuming and resulted in inconsistent quality. However, discovering Lakeland Plastics was a game-changer for us. Their ability to extrude with one side white and the other black not only eliminated the need for painting but also improved our product quality tenfold.

The team at Lakeland Plastics has been outstanding. Mary at the front desk is a true jack-of-all-trades, always providing the answers we need quickly and efficiently. Mike, the owner, and our salesperson, Phil, along with the entire shipping department, have been incredibly helpful and accommodating throughout our partnership.

We highly recommend Lakeland Plastics for their innovative solutions and exceptional customer service.

We have a 40+ year business relationship with Lakeland Plastics. They are a key business partner offering excellent products, communication, and service.

Lakeland Plastics have really exceeded our expectations. Quality work and precise production have helped my buisiness keep moving forward. I highly recommend this company to anyone for any quality product/profile they may need.

Preferential treatment is the standard for all customers at Lakeland, allowing a level playing field for everyone involved. They have worked with us for over 10 years, helping to develop a patented product and providing outstanding customer service throughout. It has been an absolute delight working with honest and caring individuals who not only work toward getting things right the first time, but they work tirelessly at making sure goals are met. We consider Lakeland part of the family, and we highly recommend their attention to detail, top level customer service and exemplary design team.

Lakeland has been arguably one of the best manufacturers I have ever worked with. I came to them with a unique extrusion use case and they were able to help with my design. They managed the project with zero friction, or high added costs. The part quality is quite honestly flawless, meeting my specific use case need. The accessibility to the team is always easy and prompt. I didn’t wait days, or weeks for quotes and was able to get my product produced and to the market in a much shorter time frame than several other mfg’s I contacted quoted. Now my product is sold in over 40 states and two countries and proudly produced in the USA. I know this is a long post and I don’t usually do reviews. However, while I maybe a small fish compared to some of their production levels/ capabilities…..my involvement with Lakeland has felt more like family than being just a number on the balance sheet. They will have my business as long as my industry need exists. Hopefully a very long time. So grateful I found this needle in a hay stack. Especially if it is an extruded product you need….highly recommend giving them a shot.

“We’ve had a long-standing partnership with Lakeland Plastics to support building our OTTOLOCK cinch lock bands. Our specifications are not simple and the Lakeland team has consistently demonstrated they are up for the job with a great approach to making the outcome better. We wouldn’t be here without Lakeland and appreciate their mindset in business and customer relationships.”

“Lakeland Plastics is a trusted partner for over 25 years…The reason I like to work with their team is because of the personal attention that they invest into their customers…I know that the job will get done on time and on budget.”

“Lakeland Plastics has been a valued partner of our company for 40+ years…They are and have consistently been one of our top tier partners – valued relationship which I would highly recommend pursuing.”

Custom extrusions are a critical part of the design and production process across a wide range of industries and are integral to today’s manufacturing workflows. Unlike mass-produced standard extrusions, custom profiles are engineered to meet exact specifications, providing manufacturers with the flexibility to create highly functional and tailored products. As industries continue to evolve, these…

Two of the most common methods for producing plastic components are plastic extrusion and thermoforming. While both processes are widely used, they’re built for different types of parts, different production goals, and different design requirements. Choosing the right manufacturing process can shape everything that follows, from product performance and consistency to lead times and long-term…

Plastic extrusion powers many of the products people use every day, from the tubing that carries fluids in hospitals to the protective coatings on electrical cables. There are many different types of plastic extrusion, but overall, the process involves taking molten plastic and shaping it into continuous, perfectly engineered forms that meet exact design requirements.…