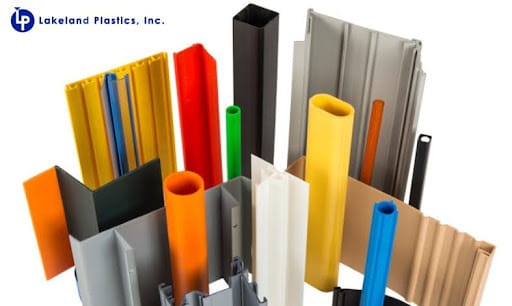

Since 1962, Lakeland Plastics has specialized in the manufacturing of custom thermoplastic profile extrusions. Our quality products are utilized by a variety of industries including point-of-purchase, lighting, refrigeration, building and construction, automotive, industrial, consumer products, electronics, water treatment and telecom.

Whether it’s creating components for machinery or crafting intricate parts for consumer products, the ability to achieve precise dimensions is crucial. One technology that excels in this arena is custom plastic profile extrusion. In this article, we’ll explore the art of custom plastic profile extrusion and how it revolutionizes manufacturing processes by ensuring precise dimensions.…

Introduction Talking about innovation, the process stands out for its remarkable contribution to superior bonding that is Crosshead Extrusion Coating. This revolutionary technique has transformed the landscape of coating applications, ensuring unparalleled durability and resilience across various substrates. Let’s delve into the intricate science behind this marvel of engineering. Unraveling Crosshead Extrusion Coating Crosshead Extrusion…

Introduction The integration of innovative materials plays a pivotal role in enhancing sustainability of green building while maximizing efficiency. One such material making significant strides in this arena is plastic extrusions. These versatile components are reshaping the landscape of construction, offering a plethora of benefits ranging from environmental friendliness to improved performance. This introduction delves…

Introduction Tri-extrusion stands as a groundbreaking technique revolutionizing material properties across industries. Through this innovative process, materials are created with enhanced strength, durability, and versatility, setting new standards for performance and application. Let’s dive into the intricacies of tri-extrusion and its profound impact on diverse sectors. What is Tri-Extrusion? Tri-extrusion is an advanced manufacturing…

Introduction Custom extruded plastic products emerge as essential components across diverse industries, their inherent strength and durability set them apart, ensuring they withstand rigorous conditions and deliver consistent performance over time. From automotive components to construction materials, these specialized products offer unmatched reliability and longevity, contributing to the efficiency and sustainability of modern manufacturing processes.…

Introduction In recent years, environmental sustainability has become a central focus across industries, prompting a critical examination of manufacturing processes and materials. Plastic extrusion, a widely used manufacturing method, has drawn attention for its environmental impact. However, by shifting focus to US-made plastic extrusions, a narrative of environmental stewardship emerges. This guide delves into…

Introduction Water treatment systems play a critical role in ensuring access to clean and safe water for communities around the world. As technology advances and environmental concerns grow, the demand for innovative solutions in water treatment continues to rise. Custom plastic extrusions have emerged as a game-changer in this field, offering versatile and cost-effective solutions…

Custom plastic extrusion stands as a cornerstone in meeting the specialized needs of industries worldwide. This article delves into the intricacies of design flexibility in custom plastic extrusion, exploring its significance, applications, challenges, and future prospects. Introduction to Custom Plastic Extrusion What is custom plastic extrusion? Custom plastic extrusion is a specialized manufacturing process focusing…

Telecom infrastructure, the backbone of our interconnected world, plays a pivotal role in facilitating communication. Amidst the intricate network of cables, towers, and data centers, there’s a silent hero—plastic extrusions. These unsung components contribute significantly to the durability, flexibility, and efficiency of the entire system. Understanding Telecom Infrastructure In the digital age, telecom infrastructure encompasses…

Signage Solutions: Making an Impact with Durable Extruded Plastics Introduction Signage solutions have become integral to our daily lives, guiding us, conveying messages, and leaving lasting impressions. In this article, we explore the significant role of durable extruded plastics in modern signage, delving into their applications, advantages, challenges, and future trends. Understanding Signage Solutions The…