What is Co-Extrusion and Tri-Extrusion?

Co-Extrusion and Tri-Extrusion is a specialized manufacturing process by which two or more (often times dissimilar) thermoplastic materials are extruded through a single die with two or more openings arranged in such a way as to allow the extruded materials to merge together into a single fused part.

The process of co-extrusion and tri-extrusion allows Lakeland plastics to combine 2 or 3 different raw materials into one extruded profile. The benefit of this process is the ability to provide different finishes, multiple colors, combinations of rigid and soft materials or other unique combinations in a cost effective solution that meets the specific needs of our clients.

Benefits of Co-Extrusion and Tri-Extrusion

The primary benefit of the co-extrusion and tri-extrusion process is that each extruded layer can impart a different characteristic or property on the finished part. Some of these properties include rigidity, softness, flexibility, heat resistance, stiffness or chemical impermeability, all of which would be impossible to achieve using any single thermoplastic material.

Uses of Co-Extruded and Tri-Extruded Parts

Oftentimes a single thermoplastic material cannot provide all the characteristics or properties that an extruded plastic part may require. There may be a requirement for a flexible hinge on a rigid part or 2 or 3 different colors in a tube, and that is where Lakeland Plastics co-extrusion and tri-extrusion capabilities can help provide a solution.

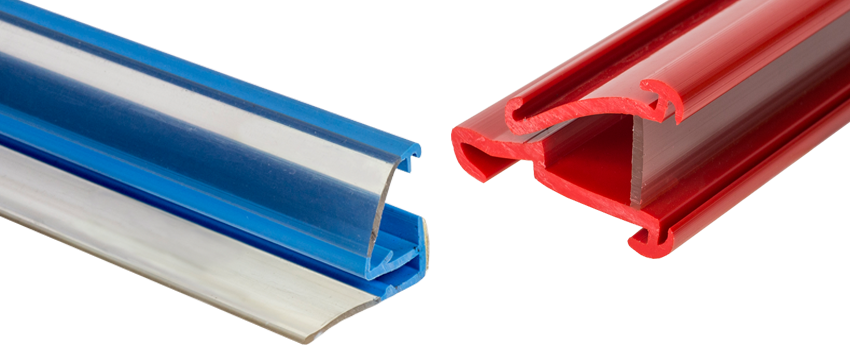

By running 2 or 3 extruders into a single die, we have the ability to combine materials of differing durometers or colors into a single extruded part. There are many configurations we can provide in co-extrusion and tri-extrusion. We can extrude multi-layer tubings, rigid parts with hinges, soft or protective skins, colored stripes and much more.

Many Point-of-Purchase (POP) display extrusions are co-extruded. POP displays make extensive use of flexible fingers for gripping and living hinges. They also make use of extrusions with a colored back and a clear front window. These are just a few examples of the many uses of co-extrusion and tri-extrusion provided by Lakeland Plastics. Whatever your custom plastic extrusion requirements may be, contact the sales engineers at Lakeland Plastics for a prompt quotation.

Lakeland Plastics is one of America’s premier Plastic Extrusion Companies specializing in top quality, precisely engineered custom plastic extrusion for virtually any industry. In addition to our high quality custom extrusion of plastic profiles, rods and tubes, we also provide technical and support services which include, Design Engineering, Plastic Extrusion Tooling, Fabrication Services as well as 3D Printing.

For those of you familiar with our tradition, thank you for your support and continued interest in the evolution of our company. For those of you that are new to our company or are searching for the best Plastic Profile Extrusion Company for your project needs, welcome to the family and we would consider it a privilege to work with you.