Custom extrusions are a critical part of the design and production process across a wide range of industries and are integral to today’s manufacturing workflows. Unlike mass-produced standard extrusions, custom profiles are engineered to meet exact specifications, providing manufacturers with the flexibility to create highly functional and tailored products.

As industries continue to evolve, these custom extruded profiles are becoming an indispensable tool for meeting exacting standards, reducing production costs, improving overall product performance, and meeting ever-increasing demands for efficiency, durability, and innovation. From intricate shapes and specialized materials to automotive seals, window frames, or custom enclosures, these custom plastic extrusion profiles offer unparalleled versatility and precision.

What Are Custom Extruded Plastic Profiles?

Custom extruded plastic profiles are precisely shaped plastic products created by forcing heated plastic through a specially designed mold or die. This process results in continuous shapes that can be cut to the required length. The flexibility of this process allows manufacturers to produce profiles with an infinite variety of shapes, sizes, and configurations, all tailored to specific applications.

Custom extrusions differ from standard extrusions in that they are uniquely designed to meet the precise needs of a manufacturer, whether that’s through shape, size, or material choice. These profiles are often used in products that require tight tolerances or specific performance features that off-the-shelf profiles simply can’t provide.

Industries such as automotive, construction, electronics, and healthcare rely on custom extrusions to fulfill their specialized requirements.

Key Features & Capabilities of Custom Extruded Profiles

Custom extruded profiles offer a wide range of features and capabilities that provide manufacturers with the flexibility and performance they need.

Custom Shapes

One of the most significant advantages of custom extrusions is the ability to create profiles in virtually any shape. From simple, straight-line designs to complex, multi-dimensional forms, the extrusion process allows manufacturers to create profiles that perfectly fit the intended application. Whether it’s a simple square tube or a highly detailed and intricate shape, custom extrusions give designers the creative freedom to explore new possibilities that wouldn’t be achievable with off-the-shelf solutions.

Materials

The selection of material plays a crucial role in the performance of the final product. Custom extruded profiles can be made from a broad range of materials, each with unique properties, such as the flexibility of polyvinyl chloride (PVC), the strength of polypropylene, or the chemical resistance of nylon. Materials can also be engineered for specific temperature ranges, making them ideal for applications in extreme environments.

Custom extrusions give manufacturers the freedom to choose the ideal material for their needs. With access to a wide variety of thermoplastics, manufacturers can make sure their products meet industry-specific requirements for strength, flexibility, chemical resistance, or UV stability.

Co-Extrusion/Tri-Extrusion

For applications that require multiple material properties in a single profile, co-extrusion and tri-extrusion offer innovative solutions.

Co-extrusion involves the extrusion of two or more different materials simultaneously, which results in a multi-layer profile that combines the benefits of each material. For example, a core material can provide strength and structure, while an outer layer offers UV resistance or a specific aesthetic finish. Tri-extrusion takes this process a step further by combining three different materials, each performing a specific role in the profile. It’s ideal for creating advanced profiles with enhanced performance characteristics, such as better insulation, chemical resistance, or specialized coatings.

Secondary Operations

After extrusion, custom profiles can undergo a variety of secondary operations that further refine the product to meet specific requirements. These processes may include cutting to specific lengths, drilling holes, bending, punching, or adding adhesives or seals. These post-extrusion operations ensure that the final product is ready for immediate use, saving manufacturers time and reducing the need for additional steps in the production process.

Secondary operations can also be customized to meet unique project specifications, which allows for an added layer of versatility and precision in the manufacturing process.

Reinforcement

Certain applications require profiles that can withstand significant stresses and pressures. By incorporating reinforcement materials such as fiberglass or carbon fiber into the extrusion process, manufacturers can produce stronger, more durable profiles without sacrificing flexibility or performance. Reinforcement materials can be added throughout the profile or selectively placed where additional strength is needed, which makes custom extrusions ideal for heavy-duty applications where strength and stability are critical, such as in the automotive and construction industries.

5 Benefits of Custom Extruded Plastic Profiles

Custom extruded profiles provide several key advantages that make them an attractive option for manufacturers looking to improve product performance and streamline their processes. Here’s a closer look at the benefits.

1. Improved Product Performance

Custom extrusions are designed to meet specific performance criteria, which can significantly enhance the functionality of the final product. They are tailored to address particular performance needs, such as a flexible seal that conforms perfectly to an irregular surface or a rigid profile that withstands high impact. This level of customization can improve product reliability, durability, and longevity, helping products perform optimally over time.

2. Reduced Costs

By using custom extruded profiles, manufacturers can reduce waste, minimize the need for additional parts, and optimize material use. For example, profiles that are specifically designed for a particular application will fit perfectly into the overall assembly, eliminating the need for costly adjustments or replacements.

Custom profiles can also be produced in the exact quantities needed to avoid excess inventory and reduce overall material costs. Additionally, the precision of custom extrusions often reduces the need for post-production adjustments, further lowering labor and operational costs.

3. Ability to Meet Precise Design & Durability Requirements

Custom extrusions offer manufacturers the ability to meet exact design specifications, which is crucial for industries that require high precision. From creating profiles for medical devices that must meet strict biocompatibility standards to designing weatherproof seals for outdoor applications, custom extrusions allow manufacturers to produce profiles that meet the most stringent requirements.

The ability to fine-tune both the design and material composition of a profile ensures that it will perform as expected under real-world conditions.

4. Better Versatility & Adaptability

The adaptability of custom extruded plastic profiles allows them to be used in a wide range of applications. Custom profiles can be designed for both functional and aesthetic purposes, and they can be adjusted as needed to fit different manufacturing processes. If a manufacturer needs a specific color, texture, or material property, custom extrusions offer the flexibility to meet a variety of requirements. As a result, they’re highly versatile for multiple industries.

5. Increased Efficiency

Custom profiles streamline production processes, allowing manufacturers to work more efficiently and reduce the time to market. For example, using custom extrusions that perfectly match the design requirements allows manufacturers to reduce the amount of time spent on rework, quality checks, and post-production adjustments.

Additionally, custom extrusions can help reduce the overall number of components in a product, further improving manufacturing efficiency and minimizing assembly time.

Common Applications of Custom Extruded Profiles

Custom extruded plastic profiles have a wide range of applications across various industries. These profiles are used in countless products that require specialized shapes, materials, and performance features.

Let’s review some of the most common uses.

Construction

In construction, custom extrusions are frequently used for window and door seals, trim, and weatherproofing profiles. These profiles help create tight seals that prevent air and water leaks, ensuring that buildings are energy-efficient and weather-resistant. Custom profiles also help with structural integrity, so they are a popular option for reinforcing various construction elements.

Automotive

The automotive industry relies on custom extrusion profiles for components like gaskets, seals, and protective profiles. These profiles must meet strict performance standards to withstand extreme temperatures, vibrations, and environmental conditions. Custom extrusions can be designed to provide insulation, prevent leaks, and enhance safety features, making them essential for manufacturing high-quality, durable vehicles.

Healthcare

The healthcare industry often requires custom extruded profiles for medical devices and equipment. These profiles must meet stringent biocompatibility and durability standards.

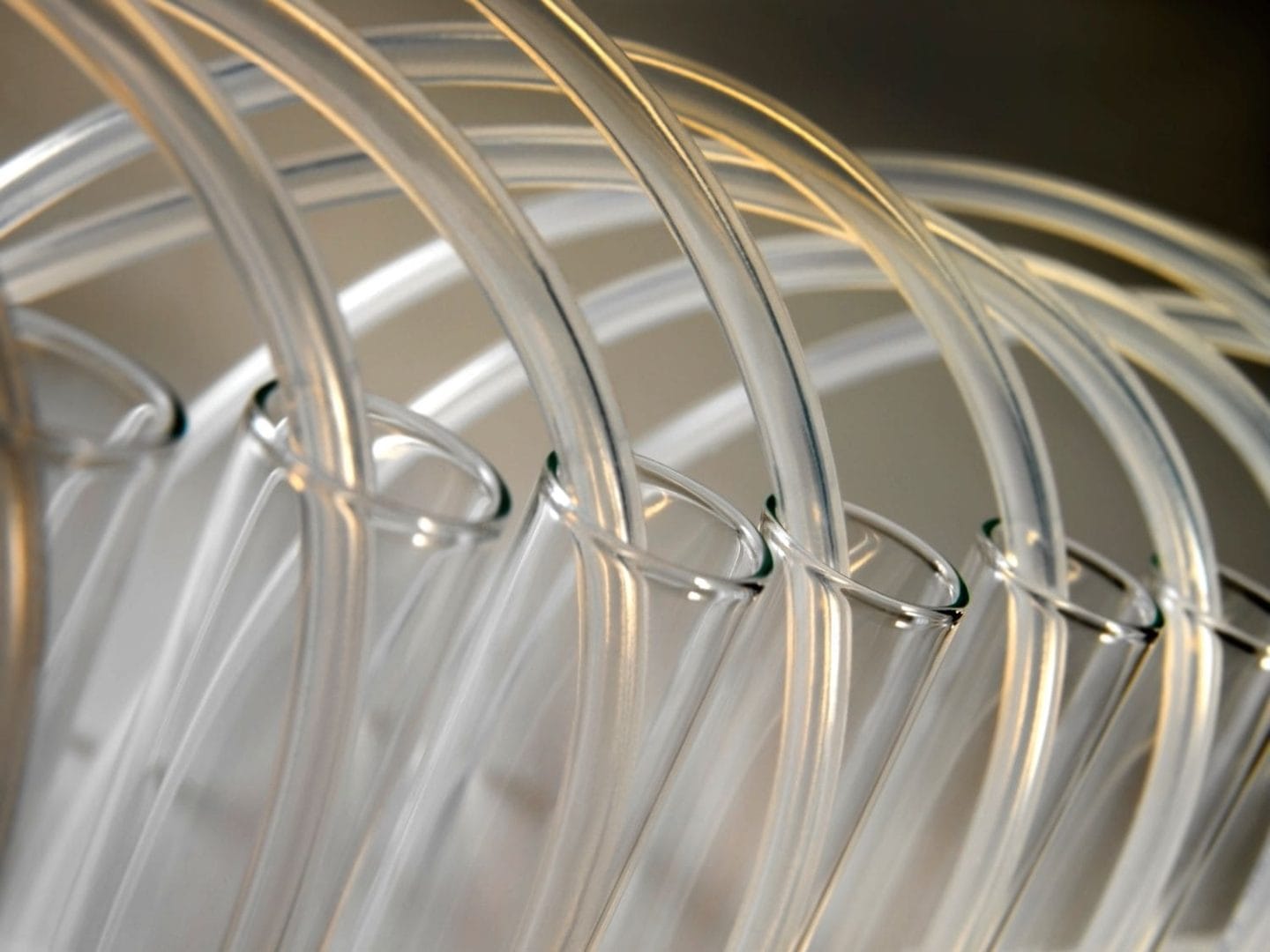

Custom extrusions are used in applications such as medical tubing, seals, and protective covers. Their ability to be engineered for both performance and safety makes them indispensable in the design and production of medical devices.

Consumer Goods

Custom extruded plastic profiles are commonly used in the production of product casings, enclosures, and decorative elements. The ability to customize the profile’s shape, color, and texture makes it ideal for creating products that are both functional and visually appealing, like custom casing for electronics or a decorative trim for furniture. In other words, custom extrusions offer the flexibility to meet a wide variety of design and functionality needs.

Electronics

Custom extrusions play a critical role in the electronics industry, where they are used for cable insulation, connectors, and housing for electrical components. These profiles help protect sensitive components from external damage, provide insulation, and make sure that electrical systems work reliably and safely. The versatility of custom extrusions allows them to be tailored to fit the unique needs of various electronic products.

What to Look for in a Custom Extruded Plastic Profile Partner

When selecting a partner for custom extrusions, manufacturers should consider several factors that can influence the quality, cost, and performance of the final product. Look for these signs as you continue on your search for a trustworthy custom extruded plastic profile partner.

Expertise & Experience

A reliable extrusion partner should have deep knowledge and experience in the field of custom extrusion. They should be familiar with the complexities of designing and producing custom profiles across a range of industries. Search for a partner with a proven track record of delivering high-quality products on time and within budget.

Material Options & Flexibility

The ideal partner should offer a wide variety of materials to choose from so they can make sure that the right material is selected for each application. A strong partner will also be able to recommend the best materials for specific performance requirements and advise you on how to optimize material properties for the intended use.

Customization Capabilities

Your extrusion partner should have the capability to create profiles in any shape, size, or material, with the ability to perform additional operations like co-extrusion and secondary processes. They should be able to meet the most complex design requirements while offering the flexibility to adapt to changes in the design process.

Quality Control & Testing

It’s essential to work with a partner who has robust quality control measures in place. Custom extrusions should undergo rigorous testing to ensure they meet the necessary standards for strength, durability, and performance. The partner should also provide clear documentation of testing results and certifications to give you peace of mind.

Production Capacity & Lead Times

Timely delivery is crucial for maintaining production schedules and meeting customer demands. When selecting an extrusion partner, it’s important to assess their production capacity and ability to scale with your needs. A reliable partner should be able to handle both small and large orders while meeting agreed-upon lead times.

Custom Extruded Profile FAQs

What Industries Use Custom Extruded Plastic Profiles?

Custom extruded plastic profiles are used across many industries, including automotive, construction, consumer goods, electronics, and healthcare. They are particularly beneficial in applications that require precise shapes, specialized materials, or high-performance standards, such as automotive seals, window trims, cable insulation, and medical device components.

How Do Custom Extruded Plastic Profiles Reduce Manufacturing Costs?

Custom extruded profiles help reduce manufacturing costs by minimizing material waste and eliminating the need for additional parts or complex assembly processes. Since custom profiles are tailored to meet exact specifications, they fit perfectly into the final product, reducing the need for costly adjustments or rework. Additionally, using custom extrusions can streamline production, which improves overall efficiency and reduces labor costs.

What Are the Different Types of Materials Used in Custom Extrusion?

Custom extruded plastic profiles can be made from a variety of materials, each with unique properties to meet different performance needs. Common materials include polyvinyl chloride (PVC), polyethylene, polypropylene, nylon, and acrylonitrile butadiene styrene (ABS). These materials can be selected based on factors such as flexibility, strength, chemical resistance, UV stability, and temperature tolerance.

Can Custom Extrusions Be Made in Any Shape or Size?

Yes. One of the primary benefits of custom extrusion is the ability to create profiles in virtually any shape or size. Whether the profile needs to be a simple straight line or a complex, multi-dimensional form, custom extrusions can be designed to meet precise specifications. This capability makes them an ideal solution for both functional and aesthetic applications.

What Is Co-Extrusion, & How Is It Used in Custom Profiles?

Co-extrusion is a process in which two or more materials are extruded together to create a multi-layer profile. It allows manufacturers to combine the benefits of different materials in a single profile, such as a durable inner core with a UV-resistant outer layer. This process is commonly used for applications that require enhanced performance, such as insulation, chemical resistance, or weatherproofing.

How Can Custom Extruded Plastic Profiles Improve Product Performance?

Custom extrusions are engineered to meet specific performance requirements, such as strength, flexibility, chemical resistance, or durability. By selecting the right materials and profile shapes, manufacturers can create products that perform better in their intended environments, withstand extreme temperatures, provide better insulation, or offer superior protection against external elements.

What Should I Look for When Choosing a Custom Extruded Plastic Profile Partner?

When selecting a partner for custom extrusions, look for a company with expertise and experience in your industry, a wide range of material options, and strong customization capabilities. The partner should also offer reliable quality control processes, have the ability to meet your production timelines, and provide value-added services like secondary operations or co-extrusion/tri-extrusion for more complex profiles.

Contact Lakeland Plastics: The Leading Plastic Extrusion Company

Custom extruded plastic profiles offer unparalleled flexibility and performance in manufacturing. From enhancing product performance to reducing costs and meeting precise design requirements, these profiles are essential in a wide range of industries.

At Lakeland Plastics, we specialize in providing high-quality custom plastic extrusions that meet the unique needs of our clients. If you’re looking for a trusted partner who can help bring your design vision to life with precision and efficiency, we’re here to help.

Contact us or request a quote today to discuss your project and learn how we can support your manufacturing process.