Plastic extrusion has become one of the most important manufacturing processes of the modern world. From the pipes beneath our feet to the packaging that preserves our food, extrusion touches nearly every aspect of daily life.

But this process didn’t emerge overnight. It’s the result of nearly two centuries of innovation, experimentation, and refinement. Exploring the history and evolution of plastic extrusion not only reveals how far we’ve come but also offers a glimpse into the exciting future of this indispensable technology.

What Is Plastic Extrusion?

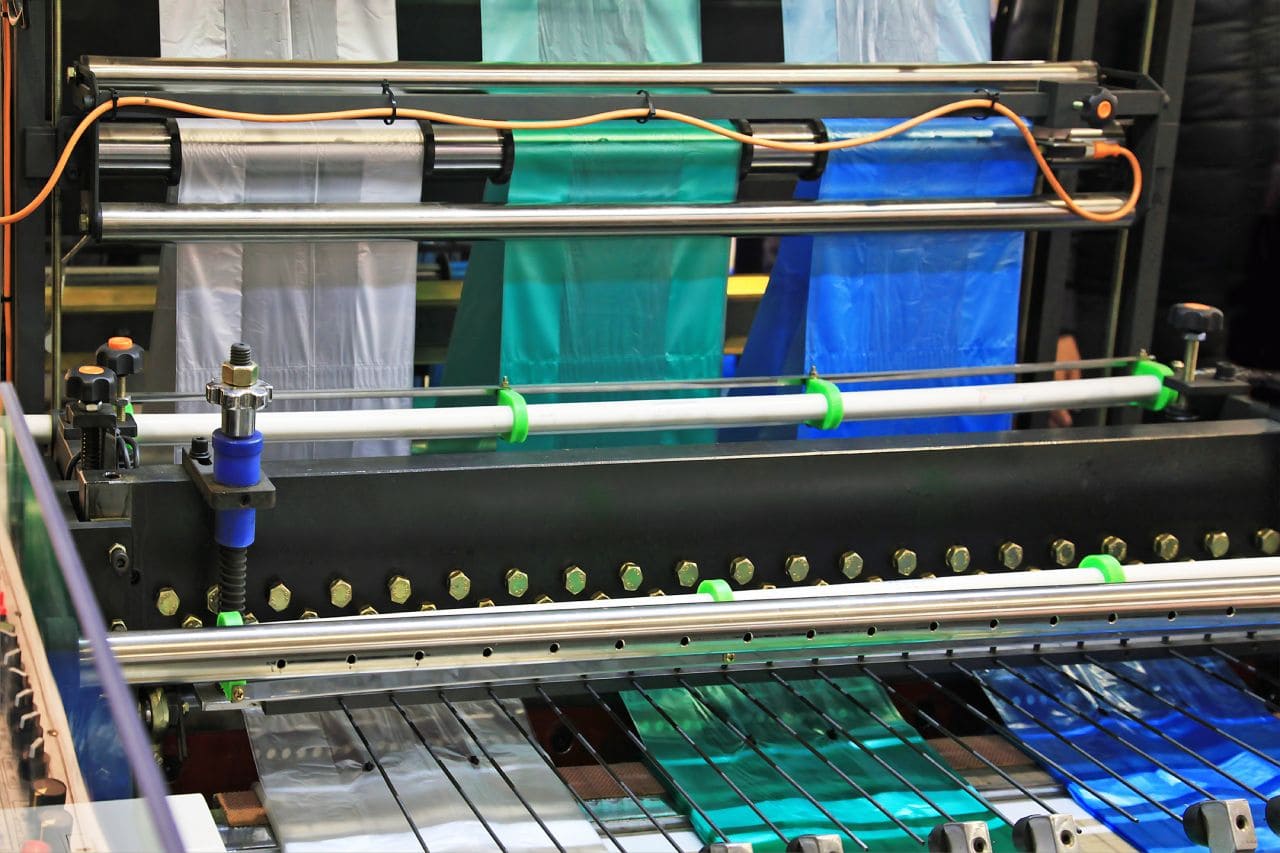

Plastic extrusion is a continuous manufacturing process that shapes raw plastic materials into long, consistent forms with fixed cross-sections.

Typically, the process begins with plastic pellets or granules that are fed into an extruder. Inside, a rotating screw pushes the material forward, where it is gradually heated until molten. The molten plastic is then forced through a precision die that gives it its final shape, whether that be tubing, pipes, sheets, films, or custom profiles. Once extruded, the material is cooled and trimmed to the required length.

This method is favored for its efficiency, versatility, and ability to produce both everyday essentials and specialized components used in industries like automotive, construction, medical devices, and packaging.

The History of Plastic Extrusion

The story of plastic extrusion is one of ingenuity and progress. What began as experiments with rubber and early synthetic materials in the 19th century evolved into a sophisticated, global industry by the 20th and 21st centuries. Each milestone brought with it greater precision, efficiency, and opportunity, all of which helped to establish extrusion as the backbone of modern plastics manufacturing.

Origins of Plastic Extrusion

The earliest precursors to modern extrusion were developed in the early 1800s. In 1820, English inventor Thomas Hancock created a rubber “masticator,” a machine designed to reclaim and reuse rubber scraps. Just 16 years later, in 1836, Edwin Chaffee of the United States developed a two-roller machine that allowed manufacturers to mix additives into rubber. While these early innovations weren’t plastics in the modern sense, they laid the foundation for extrusion technology.

The late 19th century brought the rise of synthetic thermoplastics, beginning with Parkesine (later called celluloid) in 1862. These new materials could be softened with heat and hardened upon cooling, making them ideal candidates for extrusion. This discovery set the stage for plastics to become a dominant force in the 20th century.

Early Innovations & Milestones in Plastic Extrusion

The first true thermoplastic extrusion took place in 1935, when inventor Paul Troester and his wife Ashley Gershoff successfully extruded thermoplastics in Hamburg, Germany. Around the same time, in Italy, Roberto Colombo of Lavorazione Materie Plastiche (LMP) pioneered the twin-screw extruder, a breakthrough that improved mixing and consistency in the extrusion process.

By the 1930s and 1940s, advances in polymer chemistry introduced materials like polyethylene, polystyrene, and polyvinyl chloride (PVC), each of which proved highly suitable for extrusion. Additionally, the invention of the single-screw extruder soon replaced earlier ram-style machines, providing better control of temperature, pressure, and material flow.

These innovations marked the true beginning of plastic extrusion as a reliable, scalable industrial process.

Evolution of Plastic Extrusion Over Time

During the mid-20th century, plastic extrusion entered a period of rapid expansion. By the 1950s and 1960s, it was widely used in packaging, construction, automotive parts, and household products. Polyethylene films revolutionized the packaging industry, while PVC extrusion made durable, affordable pipes and window frames available to homes and businesses worldwide.

Technological advancements in die design, cooling methods, and automation further improved product quality and efficiency. The invention of co-extrusion allowed multiple materials to be combined into a single layered product, leading to innovations like barrier films used in food packaging and medical applications.

Modern Innovations in Plastic Extrusion

Today, plastic extrusion is more advanced, efficient, and sustainable than ever before.

Computerized controls allow for unparalleled precision and maintain consistent quality across massive production runs. High-performance polymers and biodegradable plastics are opening doors to new industries and environmentally friendly solutions. Energy-efficient extruders and recycling-friendly processes reduce waste and environmental impact. In addition, 3D printing, which relies on extrusion principles, has expanded the definition of what extrusion can achieve, enabling rapid prototyping and custom manufacturing on demand.

Timeline of Plastic Extrusion Milestones & Evolution

To better understand the evolution of plastic extrusion, here is a timeline highlighting some of the most important breakthroughs, inventors, and innovations that shaped the process into what it is today.

| Year | Inventor/Organization | Milestone/Contribution |

|---|---|---|

| 1820 | Thomas Hancock (England) | Invented the rubber “masticator,” an early precursor to extrusion technology |

| 1836 | Edwin Chaffee (United States) | Developed a two-roller machine for mixing additives into rubber |

| 1862 | Alexander Parkes (England) | Introduced Parkesine (later known as celluloid), the first thermoplastic material |

| 1930s | Roberto Colombo (Italy) | Pioneered the first twin-screw extruder, improving mixing and consistency |

| 1935 | Paul Troester and Ashley Gershoff (Germany) | Achieved the first thermoplastic extrusion |

| 1940s‒1950s | Polymer chemists worldwide | Introduction of new plastics like polyethylene, PVC, and polystyrene into extrusion |

| 1950s‒1960s | Industry-wide adoption | Extrusion widely applied in packaging, construction, and consumer goods |

| 1970s‒1980s | Manufacturers globally | Co-extrusion techniques developed, enabling multilayer films and products |

| 2000s‒present | Modern innovators | Advanced polymers, biodegradable plastics, AI-controlled systems, and sustainable methods |

The Future of Plastic Extrusion: 4 Trends to Expect

The future of plastic extrusion is poised to be defined by sustainability, smarter technology, and new materials. As industries demand more eco-friendly and high-performance products, extrusion will continue to adapt and evolve in exciting ways.

1. Sustainability & Recycling

One of the most pressing areas of innovation will be sustainability. Manufacturers are moving toward closed-loop systems that recycle scrap materials back into the extrusion process, significantly reducing waste. Biodegradable plastics, bio-based resins, and advancements in mechanical and chemical recycling will allow extrusion to play a pivotal role in building a circular economy.

This shift not only helps reduce the environmental impact of plastics but also meets increasing consumer and regulatory demand for greener solutions. And as these methods mature, extrusion will become an even more environmentally responsible process.

2. Smart Extrusion Technology

The integration of artificial intelligence (AI), advanced sensors, and real-time monitoring will make extrusion smarter and more efficient.

AI can predict and correct production defects before they occur, minimizing downtime and material waste. Smart systems can also optimize temperature, screw speed, and pressure in real-time to maximize energy efficiency. The result is a more consistent, cost-effective, and reliable process that benefits both manufacturers and end users.

This data-driven approach will also make extrusion lines more adaptable and capable of producing complex products with greater precision than ever before.

3. Advanced Materials

As industries push the boundaries of performance, extrusion will increasingly utilize advanced polymers and composites.

High-performance plastics capable of withstanding extreme heat, pressure, or chemical exposure will enable new applications in aerospace, medical devices, and electronics. At the same time, bio-based polymers derived from renewable sources will gain traction as sustainable alternatives to petroleum-based plastics.

These materials will not only expand the possibilities of extrusion but also align with global efforts to reduce reliance on fossil fuels.

4. Customization & Additive Manufacturing

The fusion of extrusion with additive manufacturing, such as 3D printing, will create new opportunities for customization and on-demand production. Extrusion processes may be adapted to produce small-batch, highly specialized components with rapid turnaround times. This trend will allow manufacturers to respond quickly to unique customer needs while reducing inventory and storage costs.

Over time, extrusion and additive methods may converge, creating hybrid processes that deliver the scalability of traditional extrusion with the flexibility of 3D printing.

Partner with Lakeland Plastics for Your Next Plastic Extrusion Project

Plastic extrusion has traveled a remarkable journey, from the early days of rubber processing machines to today’s AI-powered systems and sustainable materials. Each stage of its evolution has made the process more versatile, efficient, and essential to modern life. As the industry continues to advance, the opportunities for innovation are endless.

Lakeland Plastics has been at the forefront of this evolution since 1962. We provide high-quality extrusion solutions tailored to the needs of diverse industries, have the technology and expertise to bring plastic components to life, and offer the strategic partnership necessary for long-term success. Whether you require custom profiles, precision engineering, or innovative materials, our team is ready to help.

Contact us or request a quote today to discover how to bring your plastic extrusion project to life.