Two of the most common methods for producing plastic components are plastic extrusion and thermoforming. While both processes are widely used, they’re built for different types of parts, different production goals, and different design requirements.

Choosing the right manufacturing process can shape everything that follows, from product performance and consistency to lead times and long-term cost. If your product needs a consistent shape, reliable repeatability, and efficient production at scale, plastic extrusion is often the stronger choice. Thermoforming, on the other hand, is typically better suited for molded surface areas, shallow cavities, and lightweight packaging-style components.

To make the decision easier, let’s take a closer look at how extrusion and thermoforming work, what they’re best suited for, and where the differences matter most.

What Is Plastic Extrusion?

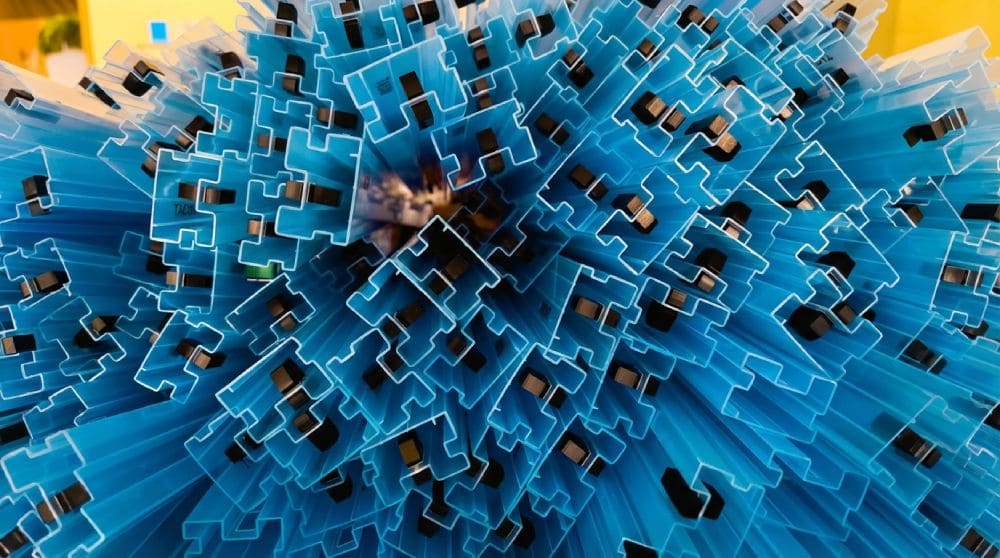

Plastic extrusion is a continuous manufacturing process used to create plastic parts with a uniform cross-sectional shape. In simple terms, plastic is melted and pushed through a specially shaped tool called a die. As the plastic flows out of the die, it forms a consistent profile that can be produced in long lengths and then cut, coiled, or further processed.

Extrusion is widely used in industries where dimensional consistency, durability, and cost efficiency matter. Because it runs continuously, extrusion supports high-volume production while maintaining a steady output, making it ideal for companies that need repeatable parts at scale.

How Plastic Extrusion Works

Plastic extrusion starts with raw plastic material—usually pellets or powder—fed into an extruder. Inside the extruder, a rotating screw moves the material through heated zones, gradually melting and mixing it into a uniform, pressurized melt.

That molten plastic is then forced through a die that shapes it into the desired profile. As the material exits the die, it’s cooled and sized to maintain dimensional consistency. The finished product may be cut to length, wound into coils, or sent through additional steps like punching, drilling, printing, or co-extrusion (where multiple materials or layers are combined).

Common Plastic Extruded Products & Applications

One of the biggest reasons plastic extrusion is used across so many industries is its versatility. Because the process creates a continuous, uniform shape, it works especially well for parts that need consistent dimensions from end to end, whether that means a few inches or hundreds of feet. Extrusion also supports a wide range of sizes, thicknesses, and functional features, which makes it a practical option for both simple and highly engineered components.

Plastic extrusion is commonly used to produce a variety of products:

- Custom profiles such as channels, trims, rails, edge guards, and protective strips

- Tubing and pipe used in medical, industrial, fluid transfer, and construction applications

- Sheet and film for packaging, protective covers, liners, and thermoforming feedstock

- Specialty components that require structural stability, consistent dimensions, or material performance properties

These extruded parts show up everywhere, from manufacturing floors and job sites to medical devices and consumer products. And because plastic extrusion can be combined with in-line machining, printing, co-extrusion, tri-extrusion, and other secondary operations, it’s often used to create finished components that are ready for assembly or installation.

Materials Used in Plastic Extrusion

Plastic extrusion works with a wide variety of resins, which allows manufacturers to match material performance to the real-world demands of the application. Depending on the environment the part will be used in—and what the part needs to do—extrusion can produce everything from rigid structural profiles to flexible protective components.

Common extrusion materials include the following:

- Polyvinyl chloride (PVC)

- High-density polyethylene (HDPE)

- Low-density polyethylene (LDPE)

- Polypropylene (PP)

- Acrylonitrile butadiene styrene (ABS)

- Acrylic

- Polyethylene terephthalate (PET)

- Nylon

Material selection often comes down to factors like strength, flexibility, chemical resistance, temperature range, and exposure to weather or sunlight. Additives and custom compounds can also be incorporated to improve performance, such as UV stabilizers for outdoor use, impact modifiers for durability, or colorants for branding and visual consistency. This flexibility makes extrusion a strong choice for products that need both consistent geometry and specific functional properties.

Advantages of Plastic Extrusion

Plastic extrusion is often preferred when manufacturers need a process that balances speed, repeatability, and long-term cost efficiency. Because extrusion runs continuously and produces a stable, consistent profile, it’s especially valuable for companies that rely on predictable output and tight control over dimensions and material performance.

Key advantages include the following:

- Efficient continuous production and high throughput

- Consistent dimensions for parts with uniform profiles

- Excellent repeatability across long production runs

- Strong material efficiency with minimal waste

- Scalable output for growing demand

- Ability to use multi-layer or multi-material designs through co-extrusion

Taken together, these benefits make extrusion a smart choice for functional parts that need to perform consistently in real-world conditions. It also supports long-run manufacturing with fewer interruptions, which can help reduce total production costs over time—especially when quality issues, part variation, and downstream rework are factored into the equation.

What Is Thermoforming?

Thermoforming is a manufacturing process that shapes plastic by heating a flat sheet until it becomes flexible and then forming it over or into a mold. The formed sheet cools and hardens into its final shape, after which it is trimmed and finished.

Thermoforming is often chosen for parts that require broad surface coverage, shallow depth, and lightweight geometry. You’ll frequently see it used for packaging, trays, covers, panels, and formed housings.

How Thermoforming Works

Thermoforming begins with a plastic sheet, either purchased or produced through sheet extrusion. The sheet is heated until it reaches a pliable state, then stretched into a mold using vacuum, pressure, or both.

Once the plastic takes the shape of the mold, it cools and solidifies. The part is then removed and trimmed to its final dimensions, often using computer numeric control (CNC) trimming or cutting fixtures. Depending on the application, thermoformed parts may go through additional finishing steps, assembly, or surface treatments.

Common Thermoformed Products & Applications

Thermoforming is widely used because it can create large, lightweight parts with formed shapes without the complexity of heavier molding processes. It’s especially common when a product needs a smooth visual surface, a shaped cavity, or a protective cover and when manufacturers want a process that supports fast iteration and efficient production.

Thermoforming is common across consumer, medical, and industrial markets, including the following:

- Packaging trays, inserts, clamshells, and blisters

- Medical device trays and sterile packaging components

- Appliance liners and interior panels

- Automotive interior panels and protective covers

- Display panels, signage, and point-of-purchase components

In many of these applications, thermoforming provides a balance of speed and flexibility. It can also support design changes more easily than processes that require more complex tooling, which makes it useful for evolving product lines and packaging requirements.

Materials Used in Thermoforming

Thermoforming relies on plastic sheet materials that heat evenly, form well, and maintain their shape as they cool. Material selection often depends on how the part will be used, whether it’s a consumer package that needs clarity and shelf appeal, a protective cover that needs impact resistance, or an industrial component that needs chemical stability.

Thermoforming commonly uses the following materials:

- High-impact polystyrene (HIPS)

- Polyethylene terephthalate glycol (PETG)

- ABS

- PVC

- Polycarbonate

- Polypropylene

Each of these materials offers different advantages. PETG, for example, is often chosen for clarity and toughness in packaging, while ABS and polycarbonate are frequently used when impact resistance and durability matter more than transparency. Like extrusion, thermoforming materials can also include additives for color, UV resistance, flame retardance, or improved performance in specific environments.

Advantages of Thermoforming

Thermoforming is often chosen for its efficiency when producing formed plastic parts, especially when the design requires surface coverage, light structural demands, or cosmetic quality. Because the process uses sheet material and molds that are typically simpler than injection molding tools, it can be a cost-effective option for many projects.

Thermoforming offers several benefits for specific applications:

- Lower tooling costs compared to injection molding

- Fast prototyping and shorter setup time for formed parts

- Good option for large parts and broad surface areas

- Strong aesthetics for consumer-facing surfaces

- Flexibility for short-to-medium production runs

For many manufacturers, thermoforming is appealing because it supports faster design iterations and can be scaled without major tooling investment. It’s also useful when the product requires a formed cavity or protective shape but doesn’t demand the tight tolerances or structural performance that a continuous extruded profile is built for.

Plastic Extrusion vs. Thermoforming: 10 Key Differences

Plastic extrusion and thermoforming can both produce high-quality plastic parts, but they’re built around different manufacturing principles. Extrusion creates a continuous profile by forcing molten plastic through a shaped die, while thermoforming begins with a flat sheet that’s heated and formed over or into a mold. Because of that fundamental difference, the two processes vary widely in the types of parts they’re best suited for, the level of dimensional control they can deliver, and how they scale over time.

Here are the most important factors to consider when comparing plastic extrusion and thermoforming.

1. How the Shape Is Created

The biggest difference between extrusion and thermoforming is how the plastic is shaped. In extrusion, plastic is melted, pressurized, and pushed through a die, which forms the material into a continuous profile with a consistent cross-section. The part is created as it exits the die and is then cooled, sized, and cut to length.

Thermoforming starts with a sheet rather than a melted stream of plastic. The sheet is heated until pliable and then stretched over or into a mold using vacuum, pressure, or both. The mold determines the final shape, and the part is cooled before being trimmed and finished.

In practical terms, extrusion shapes plastic by flowing it through a tool, while thermoforming shapes plastic by stretching it into a tool.

2. Best-Fit Part Geometry

Because plastic extrusion produces a continuous profile, it’s best suited for parts that have the same shape from end to end. Common examples include tubing, channels, trims, rails, and custom profiles used in industrial, medical, and construction applications. Extrusion is also ideal when parts need to be produced in long lengths and cut to size.

Thermoforming is better suited for parts that require formed cavities, large surface coverage, or shallow depth. Packaging trays, appliance liners, protective covers, and interior panels are all common thermoformed products. The process gives more flexibility for shaped surfaces, but it’s not built for long, uniform profiles in the way extrusion is.

3. Tooling & Setup Requirements

Plastic extrusion relies on dies and downstream tooling such as calibrators and cooling systems to produce a stable, consistent profile. While die design is highly important, extrusion tooling is often more streamlined than complex molded tools, and once the line is dialed in, it can run with steady output. Setup typically involves matching the die, material, and cooling process to achieve the target dimensions and performance.

Thermoforming uses molds that the heated sheet is formed against, along with trimming fixtures used to cut the part to final shape. Tooling can vary from simple vacuum molds to more detailed pressure-forming molds, depending on the level of detail required. While thermoforming tooling is often less costly than injection molding tools, it may require additional trimming and finishing steps that affect total production time and labor.

4. Production Speed & Scalability

Plastic extrusion is a continuous process, which makes it highly efficient for producing large quantities over time. Once the line is running smoothly, output is consistent and scalable, and production can continue for long periods with minimal interruption. This capability makes extrusion especially attractive for manufacturers that need repeatable parts at high volume.

Thermoforming is cycle-based, meaning each part (or set of parts) is produced in individual forming cycles. It can still be fast—especially for lightweight parts and packaging—but overall production speed depends heavily on heating time, cooling time, and how quickly parts can be trimmed and handled.

In other words, thermoforming can scale, but it often requires more attention to downstream finishing compared to extrusion.

5. Tolerances & Dimensional Consistency

Plastic extrusion is often chosen when tight tolerances and long-run consistency matter. Because the process uses sizing and calibration tools while the plastic is still warm, extrusion can hold stable dimensions across long lengths and across repeated production runs. It’s valuable for parts that need to fit precisely with mating components, slide into assemblies, or maintain consistent performance.

Thermoforming tends to introduce more variation because the sheet is stretched during forming, which can cause thickness changes and dimensional shifts depending on the draw ratio, cooling conditions, and part geometry.

For many thermoformed applications, especially packaging, this level of variation is acceptable. However, for parts that require high precision or structural consistency, extrusion often provides a more predictable result.

6. Material Efficiency & Scrap

The plastic extrusion process tends to be more material-efficient because most of the plastic fed into the line becomes product. Waste is typically limited to startup scrap, offcuts, or trimming from secondary operations, and in many cases, these can be reground and reused depending on the material and application requirements. When material cost and waste reduction are major priorities, extrusion often has an advantage.

Thermoforming commonly produces more scrap because parts need to be trimmed from the formed sheet, leaving a skeletal frame of leftover material. Some of that scrap can be recycled or reprocessed, but feasibility depends on the type of plastic, contamination concerns, and the performance requirements of the finished part.

7. Strength & Performance

Plastic extruded parts are often used as functional components, which means performance requirements like strength, impact resistance, and durability are frequently central to the design. Because the process creates a consistent profile with stable wall thickness, extruded components can provide reliable structural performance, especially when paired with the right material selection and additives.

Thermoformed parts can also be durable, but strength depends heavily on how much the sheet is stretched during forming. Areas of the part may become thinner, which can reduce impact resistance or rigidity depending on the design.

Thermoforming works well for protective covers and formed housings, but when a part needs consistent structural performance throughout its geometry, extrusion typically offers more predictable mechanical properties.

8. Surface Finish & Visual Appearance

Plastic extrusion produces consistent surface finishes that can be smooth, matte, or textured, depending on the die design and process settings. It also supports advanced options like co-extruded cap layers that improve appearance, weatherability, or wear resistance. For many functional parts, the finish is both aesthetic and performance-driven, such as reducing friction or improving outdoor durability.

Thermoforming can deliver excellent cosmetic surfaces, especially with pressure forming, which allows for sharper detail and more uniform visual appearance. Thermoformed parts are often chosen for packaging and consumer-facing components where appearance matters as much as function.

In general, extrusion offers more control for consistent profiles and engineered finishes, while thermoforming offers strong aesthetic results for shaped surfaces.

9. Design Flexibility

Plastic extrusion is limited to parts that can be defined by a cross-section, which means it’s not meant for complex three-dimensional geometry. However, within that cross-section, it offers substantial engineering flexibility. Profiles can include internal cavities, multiple walls, snap features, and functional elements, and the process can be combined with co-extrusion, in-line punching, and other operations that add complexity without slowing production.

Thermoforming offers greater freedom in the overall 3D form of a part because the sheet can be molded into cavities, contours, and broader shapes. That said, thermoforming design is still constrained by factors like draft angles, maximum depth, and material thinning in high-draw areas.

Thermoforming excels for formed surfaces and cavities, while plastic extrusion excels for engineered profiles that need consistent geometry and repeatable output.

10. Cost Considerations

When evaluating cost, it’s important to compare total production cost—not just tooling—based on volume, quality requirements, and finishing needs.

Plastic extrusion often offers strong long-term cost efficiency for products that can be produced as a continuous profile. Output is high, so scrap is typically low, and secondary operations can often be integrated into the line; as a result, the cost per unit can become very competitive at scale. Tooling costs vary by profile complexity, but the process generally supports stable production once the setup is optimized.

Thermoforming can offer lower upfront tooling costs for formed parts, especially compared to injection molding, and it can be a fast route to early-stage production. However, per-part cost may increase due to trimming, handling, and scrap rates, particularly for thicker materials or more complex parts.

How to Choose Between Plastic Extrusion & Thermoforming for Your Product

Selecting the right process begins with clarity around your part geometry, performance needs, and long-term production goals. The most productive way to decide which process is best for your product is to work backward from what the part must do, how it will be used, and how consistently it needs to perform over time.

Start with Product Geometry

Begin with the simplest, most important question: Does your part require a consistent cross-section from end to end? If the answer is yes, extrusion is usually the most natural fit because the process is built to produce uniform profiles in continuous lengths. It excels when the design is defined by a single cross-section, such as channels, trims, rails, tubing, and structural profiles.

If the part requires formed cavities, contoured surfaces, or broad panels with varying depth, thermoforming may be the better match. Thermoforming is designed to create shaped surfaces from sheet material, which makes it well suited for trays, liners, covers, housings, and packaging-style components.

Compare Performance Requirements

Next, focus on performance and how the part will behave in real-world conditions. Consider where the part will live (indoors, outdoors, exposed to chemicals, heat, or impact, etc.) and how much stress it will experience during use. These details will shape both material selection and process choice.

Plastic extrusion is often preferred when functional performance and consistency matter most, such as when the part needs stable wall thickness, repeatable dimensions, and reliable mechanical properties. Thermoforming can still deliver durable parts, but performance is more dependent on part geometry and how much the sheet stretches during forming, which can create thinner areas that behave differently under load.

Estimate Production Volume & Cost Per Unit

Once you understand the geometry and performance demands, look at production volume and long-term cost.

Plastic extrusion is typically a strong value for products that will be produced continuously over time, especially when high throughput, low scrap, and repeatability help drive down the cost per unit. Thermoforming can be a cost-effective option for formed parts, particularly when runs are short-to-medium and tooling budgets need to stay lean.

However, it’s important to look beyond tooling cost alone and factor in trimming, scrap rates, part handling, and any downstream finishing that may affect total cost at scale.

Consider Lead Time & Speed to Market

If speed matters, compare how quickly each process can move from concept to production-ready parts. Thermoforming is often a fast path for prototyping and early-stage validation, especially when the part is packaging-like or does not require tight tolerances. Design adjustments can also be easier to make when molds and trimming fixtures are relatively straightforward.

Alternatively, plastic extrusion can also move quickly once tooling is approved, and it becomes especially efficient when you need consistent output over long runs. If your product is heading toward steady, repeatable demand, extrusion often delivers better long-term production efficiency after the initial setup is optimized.

Account for Secondary Operations & Assembly

Most parts require more than one manufacturing step, so it’s worth thinking through what happens after the part is formed.

With plastic extrusion, many secondary operations can be integrated directly into the production line, such as cutting, drilling, punching, printing, adhesive application, and co-extrusion, helping reduce handling and streamline downstream assembly. Thermoformed parts typically require trimming as a standard finishing step, and they may involve more handling before they’re production-ready.

If your product requires tight fit-up with other components, consistent hole placement, or repeatable assembly features, extrusion can be a more straightforward path because the profile is created with stable geometry and predictable dimensions.

Define Quality Expectations & Consistency Needs

Finally, consider what level of variation is acceptable for your product. If the part needs to fit precisely, slide into an assembly, seal against another component, or maintain consistent performance across long production runs, the process choice becomes critical.

Plastic extrusion is often the best option when manufacturers need dependable output and stable tolerances over time. Thermoforming is a strong choice for many packaging and formed surface applications, but when quality requirements are tight and repeatability drives downstream efficiency, extrusion often provides the consistency manufacturers rely on.

Talk with an Experienced Manufacturer Before Finalizing Your Process

Even with a clear understanding of geometry, performance needs, cost, and lead time, it’s worth reviewing your design with a manufacturer who works with these processes every day.

The biggest risk in choosing between plastic extrusion and thermoforming is committing to a method too early, before the design has been evaluated against real production constraints. An experienced partner can help you confirm whether your part is naturally suited for thermoforming or whether extrusion will deliver better dimensional stability, tighter tolerances, and more predictable performance across long runs.

This kind of guidance becomes especially valuable when your product needs consistent fit-up, repeatable assembly features, or scalable production efficiency as demand grows. In many cases, parts that seem like thermoforming candidates can be adjusted into extrusion-friendly profiles, reducing secondary operations, lowering scrap, and improving cost per unit over time.

A manufacturer can help identify those opportunities early—before tooling is built—so you choose the process that supports both immediate production needs and long-term consistency.

Contact Lakeland Plastics: The Leading Plastic Extrusion Company

Plastic extrusion and thermoforming are both proven manufacturing methods, but they serve different purposes. Thermoforming is a strong choice for packaging-style parts, formed trays, and large panels with shallow geometry. Plastic extrusion is typically the preferred choice for functional components that require consistent dimensions, reliable performance, and scalable production.

If you’re evaluating extrusion vs. thermoforming for your next product, the best starting point is your part geometry and the performance demands of the application. From there, production volume, tolerances, and downstream operations can help clarify the right path.

At Lakeland Plastics, we help manufacturers design and produce custom extruded plastic profiles and components built for repeatability, efficiency, and performance. If you have a drawing, product concept, or specification in mind, our team can help you evaluate material options and determine the right plastic extrusion solution for your application.

Contact us or request a quote today to discuss your project and discover how our expertise can move your vision forward.