The Role of Plastic Extrusions in Sustainable Lighting Solutions

Lighting is an integral part of our daily lives, and as we navigate towards a more sustainable future, the role of plastic extrusions in providing eco-friendly lighting solutions becomes increasingly crucial.

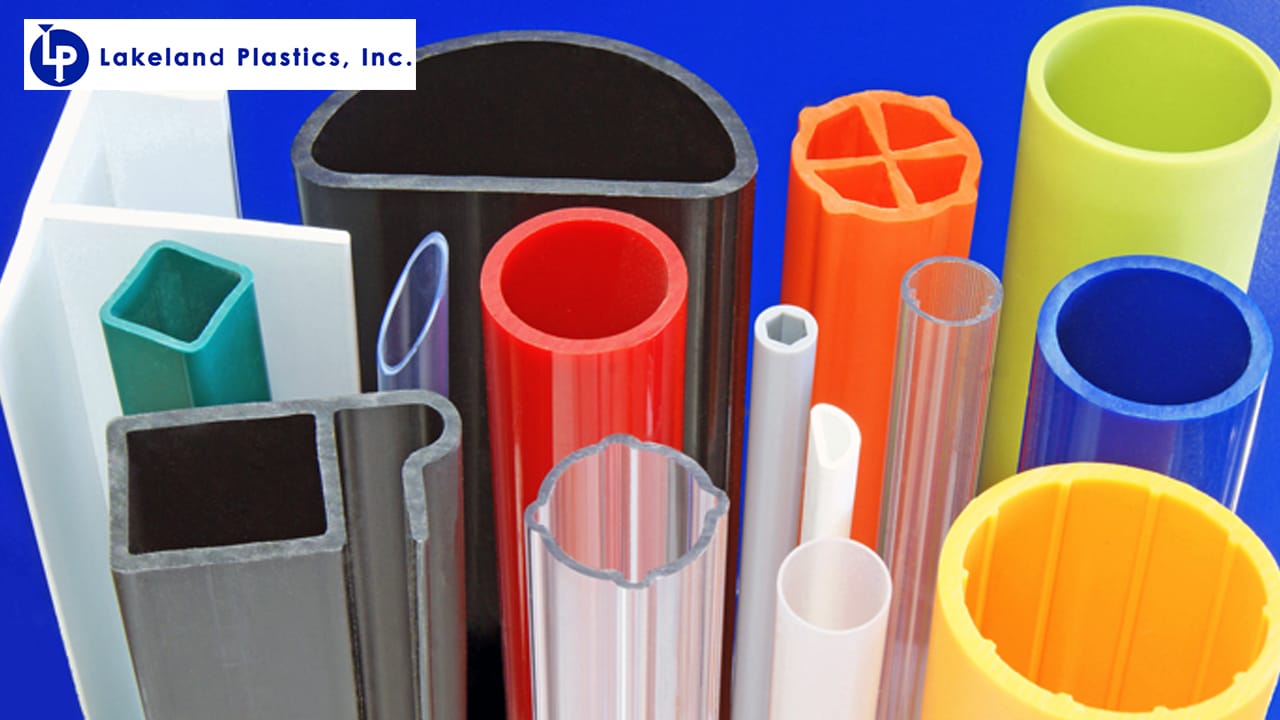

Understanding Plastic Extrusions

Plastic extrusions, in the context of lighting, involve the process of shaping plastic materials into desired forms. This method offers unparalleled versatility, allowing for intricate designs and seamless integration into various lighting solutions.

The Need for Sustainable Lighting

As the environmental impact of traditional lighting methods becomes evident, there is a growing demand for sustainable alternatives. Plastic extrusions emerge as a promising solution, addressing the need for eco-friendly lighting without compromising on efficiency or aesthetics.

Plastic Extrusions in Lighting Design

One of the key advantages of plastic extrusions lies in the flexibility it offers in lighting design. Manufacturers can tailor products to meet specific requirements, aligning with modern aesthetic trends and consumer preferences.

Benefits of Plastic Extrusions in Sustainability

Plastic extrusions contribute significantly to sustainable lighting solutions. The inherent properties of plastic, such as energy efficiency and recyclability, make it an environmentally conscious choice for both residential and commercial lighting needs.

Applications in Various Lighting Solutions

From residential spaces to commercial and industrial applications, plastic extrusions find versatile applications in different lighting solutions. Their adaptability makes them suitable for various environments, providing a consistent and energy-efficient lighting experience.

The Manufacturing Process of Plastic Extrusions

Understanding the manufacturing process sheds light on the efficiency and precision of plastic extrusions. Advancements in technology have streamlined the production, resulting in high-quality and customizable lighting components.

Cost-Effectiveness of Plastic Extrusions in Lighting

While there might be an initial investment in adopting plastic extrusions for lighting, the long-term benefits outweigh the costs. Comparative analyses showcase the cost-effectiveness of these solutions, particularly when considering energy savings and reduced maintenance expenses.

Environmental Impact and Sustainability

Choosing plastic extrusions for lighting contributes to a reduced carbon footprint. The recyclable nature of plastic ensures that waste is minimized, aligning with the global effort to create a more sustainable and eco-friendly future.

Challenges and Solutions

While plastic extrusions offer numerous benefits, it’s essential to address common concerns. Innovations in the field continuously strive to overcome challenges, ensuring that these solutions remain viable and effective in a variety of applications.

Future Trends in Sustainable Lighting with Plastic Extrusions

The future of lighting is marked by technological advancements and innovative approaches. Plastic extrusions are expected to play a significant role in shaping the landscape of sustainable lighting, offering more efficient, cost-effective, and environmentally friendly solutions.

Comparative Analysis: Plastic Extrusions vs. Conventional Lighting Materials

Efficiency, durability, and environmental impact are critical factors when choosing lighting materials. A comparative analysis between plastic extrusions and conventional materials aids in making informed decisions, considering both performance and sustainability.

Regulatory Compliance and Standards in Plastic Extrusions

Adhering to industry regulations and standards is paramount. Plastic extrusions, when manufactured following established guidelines, ensure not only the quality and safety of the products but also compliance with relevant industry standards.

Conclusion

In conclusion, the role of plastic extrusions in sustainable lighting solutions is undeniable. From its versatile applications to the environmental benefits it offers, plastic extrusions represent a forward-thinking approach to lighting that aligns with the global push for sustainability.

At Lakeland and Plastics, we bring efficiency, durability, and sustainability to every project. Explore our tailored services for lighting applications, and let us illuminate your spaces with precision and innovation. Trust Lakeland and Plastics for unparalleled expertise in shaping a brighter future through cutting-edge plastic extrusions.

Frequently Asked Questions (FAQs)

Can plastic extrusions be used for outdoor lighting?

Yes, plastic extrusions are suitable for outdoor lighting applications, providing durability and weather resistance.

How do plastic extrusions contribute to energy efficiency?

The design flexibility of plastic extrusions allows for efficient lighting layouts, reducing energy consumption.

Are there limitations to the customization of plastic extrusions in lighting design?

While highly customizable, certain intricate designs may pose challenges, but continuous innovations are addressing such limitations.

Do plastic extrusions have a significant impact on reducing maintenance costs?

Yes, the durability and longevity of plastic extrusions often result in reduced maintenance expenses compared to traditional lighting materials.

Are there any recycling facilities for end-of-life plastic extrusions from lighting applications?

Recycling facilities are available for end-of-life plastic extrusions, contributing to the sustainable lifecycle of these materials.