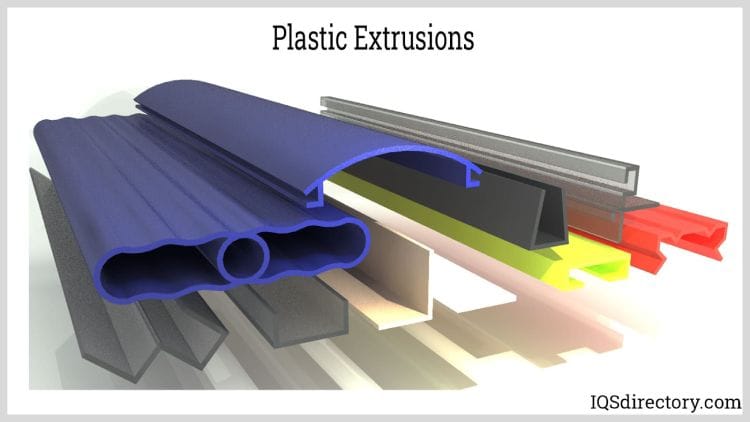

Plastic extrusion has become one of the most widely used manufacturing processes in the modern world, shaping countless products that businesses and consumers rely on every day. By heating raw plastic materials and forcing them through precision dies, manufacturers can create continuous profiles with exacting shapes and dimensions. The process is incredibly adaptable and allows companies to tailor products to highly specific performance, safety, and aesthetic requirements.

The real power of plastic extrusion lies in its versatility across industries. Unlike other processes that may serve narrow purposes, extrusion allows for customized solutions that meet diverse needs. Plastics can be formulated to resist impact, withstand extreme temperatures, diffuse light, or provide insulation. Extruded profiles can be produced at scale without sacrificing quality or consistency, making them extremely popular in sectors as varied as construction, telecommunications, and consumer goods.

To understand the impact of this process, it’s worth exploring how plastic extrusion is applied in different industries and why it remains the preferred choice for so many applications.

Industrial Applications

The industrial sector is one of the largest consumers of extruded plastic products. Factories, warehouses, and production facilities require durable components that keep machinery running smoothly, promote safety, and minimize operational downtime.

Because extruded plastics can be engineered for toughness, chemical resistance, or flexibility, they have become indispensable in this demanding environment.

Protective Tubing & Conduits

Protective tubing and conduits made through plastic extrusion safeguard sensitive wiring and cabling from harsh conditions. In automotive plants, for instance, extrusion is used to shield the wiring harnesses that power assembly robots. Aerospace manufacturers depend on lightweight extruded conduits that withstand extreme temperatures, protecting avionics from electrical interference. Heavy equipment operators also rely on chemical-resistant tubing to safeguard hydraulic and pneumatic systems from exposure to oils, solvents, and dust.

Machine Components

Machine builders often rely on extruded plastic profiles for guides, rails, and wear strips. In manufacturing and assembly lines, extruded nylon or acetal rails are used to provide durable, low-friction surfaces that keep conveyor systems running smoothly and quietly. Packaging companies use extruded plastic wear strips to minimize downtime caused by metal-on-metal contact, while automated distribution centers integrate extruded profiles into sorting machines to handle high-volume operations without failure.

These real-world applications highlight how extrusion helps industries reduce maintenance, extend equipment lifespan, and improve operational efficiency.

Packaging & Handling

Industrial packaging and handling systems also benefit from plastic extrusion.

Edge protectors and pallet components fabricated from extruded profiles protect delicate electronics during international shipping, which helps devices arrive undamaged. Agricultural producers often rely on extruded edge guards to secure and protect large shipments of glass bottles or machinery parts. Even in e-commerce fulfillment centers, extruded plastic corner protectors are used to safeguard boxes and reduce product damage claims.

Lighting Applications

The lighting industry requires components that combine technical functionality with aesthetic appeal. Extruded plastics allow for the creation of highly specialized profiles that support advanced lighting systems, improve energy efficiency, and accentuate architectural design.

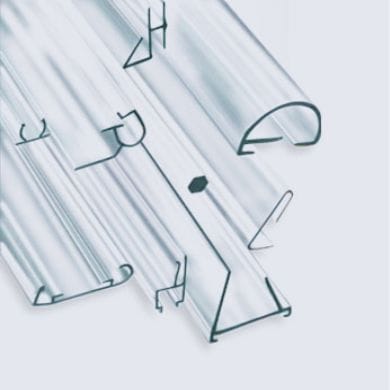

Diffusers & Lenses

Extruded diffusers and lenses play a critical role in shaping light output. In hospitals, diffusers are used in overhead fixtures to reduce glare, supporting comfortable environments for both patients and medical staff. Corporate offices use extruded polycarbonate lenses to evenly distribute light from LED panels, which improves productivity by minimizing eye strain. Retail chains adopt customized acrylic diffusers to highlight merchandise displays and draw attention to products through balanced illumination.

Reflector Housings

Lighting efficiency depends on directing light exactly where it’s needed, and reflector housings made from extruded plastics provide this precision.

Warehouses, for example, use extruded reflectors in high-bay lighting systems to maximize brightness while minimizing energy costs. Street lighting systems incorporate extruded housings with reflective surfaces that improve visibility on roadways while conserving electricity. In sports arenas, customized reflector extrusions allow light to spread evenly across playing surfaces, improving the experience for athletes and spectators alike.

Architectural Lighting

Linear extrusions used in architectural lighting represent one of the fastest-growing applications. Hotels employ sleek extruded aluminum-look plastics to frame LED strips in lobbies and create inviting ambiances. High-end retailers rely on custom-colored linear extrusions to highlight merchandise, while residential builders incorporate recessed profiles into kitchens and bathrooms for modern, minimalist aesthetics.

Construction & Building Applications

Construction & Building Applications

Plastic extrusion plays a foundational role in the construction industry. Since construction projects demand consistency and reliability, extrusion provides the scalability and precision necessary to meet these expectations. Builders and architects rely on extruded profiles for products that increase energy efficiency, enhance durability, and improve overall design aesthetics.

Window & Door Profiles

Extruded plastic profiles form the backbone of modern window and door systems. Residential homebuilders use vinyl window frames to deliver cost-effective energy efficiency, while high-rise developers specify custom extruded profiles to withstand high winds and temperature fluctuations. In commercial office towers, extruded plastic door trims are chosen for their ability to combine aesthetic appeal with long-term performance.

Weather Stripping & Gaskets

Energy efficiency is a priority in today’s green building practices, and extruded gaskets and weather stripping are crucial in sealing gaps. Residential builders use extruded seals in energy-efficient homes that meet LEED standards. Large-scale facilities like airports and hospitals integrate custom extrusions to boost HVAC performance, reducing costs while maintaining indoor comfort. Even historic building renovations rely on modern extruded gaskets to improve insulation without altering architectural aesthetics.

Wall & Ceiling Trim

Extruded plastic trims provide both decorative appeal and protection. Schools use moisture-resistant trims in high-humidity environments like locker rooms, while hotels employ decorative extruded moldings to create upscale finishes. Contractors renovating commercial kitchens often choose extruded trims that resist bacteria and moisture to help maintain compliance with health codes.

Electrical Raceway Systems

Electrical raceways and conduits made from extruded plastics are widely used in residential, commercial, and industrial projects. Data centers depend on extruded raceways to neatly organize complex wiring systems while protecting them from overheating. Hospitals use them to manage critical medical equipment wiring safely. In new residential builds, plastic conduits allow electricians to install wiring quickly and affordably, while supporting compliance with electrical safety standards.

Refrigeration Applications

Refrigeration systems, whether in supermarkets, restaurants, convenience stores, or large-scale industrial facilities, depend heavily on plastic extrusion for critical components that maintain efficiency and reliability under demanding conditions. Extruded parts are engineered to withstand constant temperature fluctuations, moisture exposure, and heavy usage cycles that occur in commercial environments.

Without the durability and precision offered by these extruded profiles, refrigeration systems would struggle to meet the rigorous standards of modern retail, food service, and industrial operations.

Door Seals & Gaskets

Refrigeration efficiency begins with the integrity of door seals and gaskets. In grocery stores, extruded gaskets keep freezer and cooler doors tightly closed, helping perishable goods remain fresh. Restaurants rely on durable custom extrusions for walk-in coolers, preventing energy loss while maintaining food safety standards. Beverage companies use extruded seals in vending machines and drink coolers, where constant use demands long-lasting, flexible gaskets that can endure thousands of opening cycles.

Spacer Bars

Extruded spacer bars in double-pane glass units provide insulation by maintaining consistent separation between panes.

Supermarket display freezers rely on these bars to minimize condensation, allowing customers to clearly see products inside. Convenience stores use spacer bars in refrigerated beverage cases to keep glass fog-free, maintaining an attractive presentation. Even large cold storage warehouses utilize extruded spacers to improve thermal efficiency and reduce the energy burden of keeping massive spaces cooled.

Protective Liners

Interior protective liners made from extruded plastics shield refrigeration units from impacts caused by stocking and cleaning. Grocery retailers use liners to prevent damage from carts and crates when restocking shelves. Fast food chains rely on stain-resistant liners that withstand spills and frequent cleaning. Industrial refrigeration facilities use heavy-duty liners to handle the constant movement of pallets and forklifts, extending the lifespan of costly equipment.

Point of Purchase (POP) Applications

Retail environments are highly competitive, and point of purchase displays are critical for attracting customer attention and driving immediate purchasing decisions. Unlike permanent signage, these displays are often temporary, seasonal, or campaign-specific, which means they must be cost-effective to produce, easy to assemble, and durable enough to endure heavy use.

Extruded plastic profiles meet all of these requirements by providing versatile and customizable components that can be tailored to fit unique display configurations and are not only visually engaging but also able to withstand the wear and tear of busy retail environments.

Display Channels & Holders

Ticket rails, shelf edging, and sign holders are produced through extrusion to provide precision and consistency. Grocery chains use extruded shelf strips to display prices and promotions clearly. Electronics stores rely on ticket rails to highlight features of high-end products. Pharmacies adopt durable extruded sign holders for promotions in checkout aisles, where displays must handle constant interaction.

Protective Edge Guards

Displays endure constant handling, and extruded edge guards provide essential protection.

Big-box retailers use edge guards on seasonal displays to prevent damage from shopping carts and heavy foot traffic. Specialty clothing stores integrate extruded guards into display tables to maintain a polished look throughout busy shopping seasons, and luxury retailers use protective extrusions to preserve the pristine appearance of high-value displays.

Custom Display Frames

Custom extruded frames add a finishing touch to promotional displays. Beverage companies often use them in branded coolers to frame promotional signage. Cosmetic brands incorporate custom extruded frames in point-of-sale displays to enhance product presentation and align with premium branding.

Additionally, trade shows frequently showcase booths with extruded frames that provide structure while maintaining sleek aesthetics.

Consumer Product Applications

From household items to recreational equipment, consumer products often rely on extruded plastics for parts that must balance function, appearance, and affordability.

Because consumers expect products that are durable, attractive, and cost-effective, manufacturers turn to extrusion as a process that can deliver all three simultaneously. Extruded plastics allow for the creation of sleek, lightweight, and ergonomically designed components that improve user experience while also lowering production costs. Their versatility also supports rapid innovation in consumer markets, where trends change quickly and the ability to produce new designs at scale provides companies with a critical competitive edge.

Household Goods

Many everyday products incorporate extruded plastic components. Storage bins often feature extruded edging to prevent cracking under stress, and it is used by furniture manufacturers to protect desks and shelving units from chipping. Cleaning tools such as mops and brooms use extruded handles for improved ergonomics and durability.

Appliance Parts

Home appliances such as refrigerators, washing machines, and microwaves depend on extruded profiles for trim, handles, and seals. For example, refrigerator manufacturers use extruded seals to improve insulation and energy efficiency. Washing machine makers rely on extruded trim profiles for noise reduction and structural stability. Microwave manufacturers use custom extruded handles that balance functionality with sleek design.

Sports & Recreation Equipment

Plastic extrusion also contributes to sports and recreation by producing grips, tubing, and protective edges for equipment.

Bicycle manufacturers integrate extruded grips for better traction and comfort during long rides. Gym equipment companies use extruded plastic tubing to cover weight racks and machines, protecting users from injury. Sporting goods brands apply extruded edges to rackets, skis, and helmets, which improves both safety and durability.

Water Treatment Applications

Water treatment facilities demand components that can withstand constant exposure to moisture, pressure, and potentially corrosive conditions. These environments are some of the most challenging for any material, requiring parts that are not only durable but also safe for use in systems that provide clean water for public consumption.

Plastic extrusion offers the flexibility to create tubing, piping, frames, and protective housings that maintain structural integrity over time, even in the presence of chemicals and high-pressure flow. By enabling consistent, customized production, extrusion allows water treatment plants to operate reliably, lower maintenance costs, and comply with stringent regulatory standards.

Tubing & Piping

Extruded plastic tubing and piping are widely used in water treatment because they resist corrosion, are lightweight, and offer long service lives compared to traditional materials.

Municipal water systems use extruded polyvinyl chloride (PVC) piping to distribute clean water to homes and businesses. Industrial water treatment plants rely on high-density polyethylene (HDPE) extrusions for their chemical resistance and durability under high pressure. And even small-scale filtration systems for residential use benefit from plastic extruded tubing that maintains water purity while keeping systems cost-effective.

Filter Frames

Filter frames produced through extrusion provide stable housings for filtration media. Large municipal plants integrate extruded frames in sand and carbon filtration units, which help maintain consistent water quality across thousands of households. Portable water purifiers also use extruded frames to house compact filters that deliver clean water in remote locations.

The versatility of extrusion allows for both large-scale infrastructure and small, consumer-grade applications.

Protective Casings

Protective casings made from extruded plastics help shield pumps, membranes, and other sensitive equipment from environmental and mechanical damage.

Desalination facilities often use heavy-duty casings to protect membranes from salt corrosion. Wastewater treatment plants adopt extruded casings for pumps to extend service life under constant operation, and mobile water treatment units deployed for disaster relief depend on extruded housings to deliver dependable performance in challenging field conditions.

Telecom Applications

Telecom Applications

The telecommunications industry requires robust infrastructure to support modern communication networks, from local broadband installations to global fiber optic backbones. Extruded plastics play a pivotal role by providing durable, lightweight, and customizable solutions that protect sensitive systems and streamline large-scale installations.

Because telecom equipment often operates in demanding environments—whether underground, underwater, or in outdoor utility enclosures—extruded plastic profiles are engineered to resist moisture, UV exposure, and mechanical stress. They are indispensable to the reliability and expansion of modern communication networks.

Cable Management Systems

Extruded conduits and wire ducts streamline the installation and maintenance of complex cable systems.

Telecommunications companies use them in broadband rollouts to organize thousands of cables under city streets. Data centers depend on extruded ducts to manage high-density wiring for servers and storage systems. Residential contractors also integrate extruded conduits to install fiber-to-the-home connections quickly and neatly.

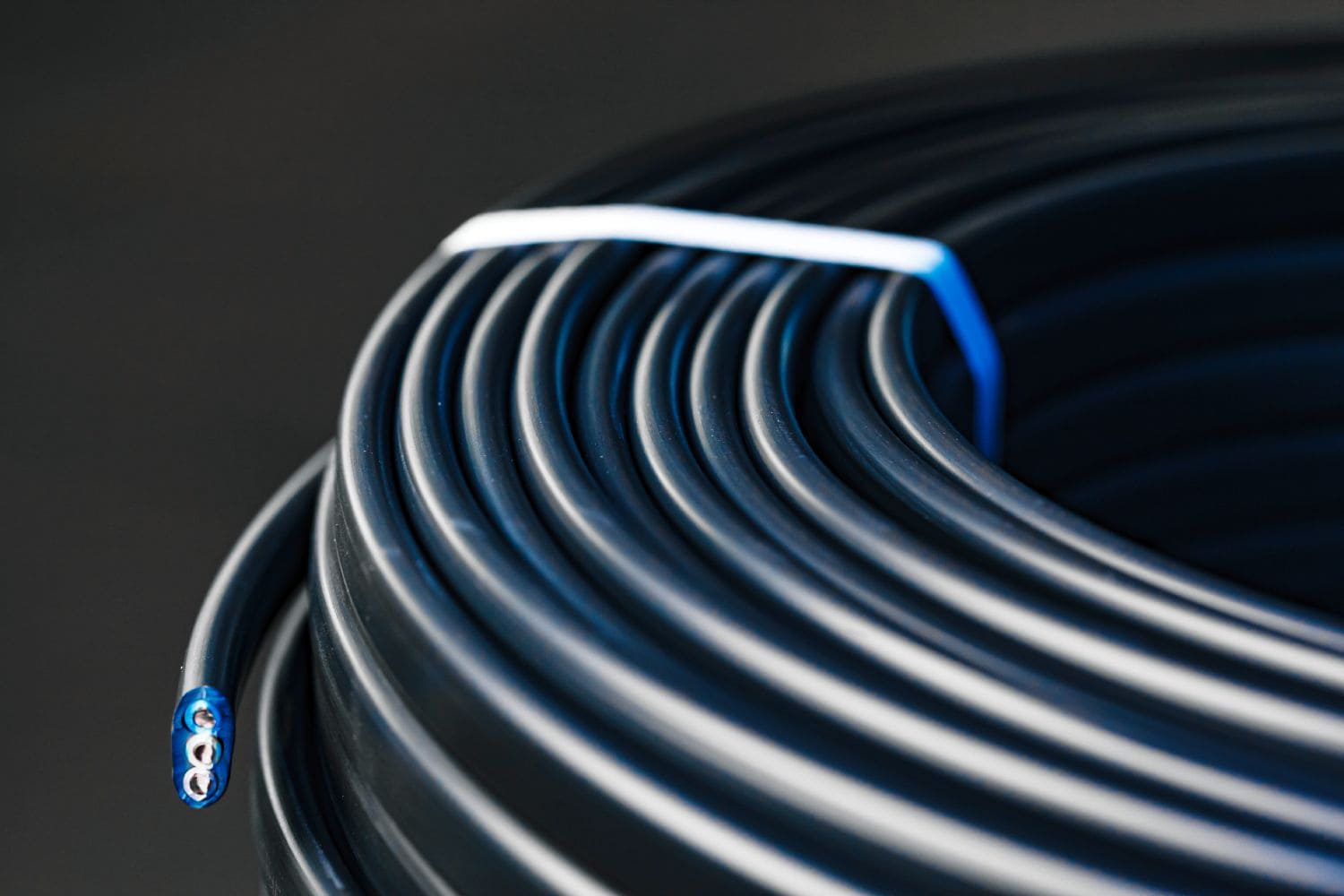

Protective Sleeves

Fiber optic and copper cables are essential to modern communications, and protective sleeves made from extruded plastics safeguard them from moisture, UV rays, and mechanical stress. Internet providers use heavy-duty extruded jackets to protect underground fiber optic lines from soil moisture and pressure. Satellite communication systems rely on UV-resistant sleeves to protect cables exposed to direct sunlight. In undersea cabling, protective extruded jackets are engineered to resist saltwater corrosion and mechanical stress from ocean currents.

Mounting Channels

Mounting channels produced through extrusion provide secure installation points for telecom hardware. Cellular networks use extruded mounting systems to stabilize 5G antennas on rooftops and towers, and utility companies rely on extruded channels to support hardware in underground vaults. Similarly, residential installations benefit from extruded channels that keep modems, routers, and cables mounted securely for easy maintenance.

Signage Applications

Signage serves both functional and branding purposes, and extruded plastics provide the durability and versatility needed to meet these dual demands. Beyond simply framing a message, extruded profiles allow signs to withstand environmental stressors, retain vibrant appearances, and adapt to custom design requirements.

With the ability to create consistent, high-quality components at scale, extrusion helps signage remain reliable and visually compelling, whether placed in high-traffic retail locations, outdoor environments exposed to weather, or specialized installations like trade shows and events.

Frames & Trim

Extruded frames and trims offer strength and stability for signs while enhancing their appearance. Retailers often use extruded frames to border promotional posters in storefront windows. Outdoor advertising companies rely on weather-resistant trims to keep billboards intact under constant exposure to rain and sunlight. Trade show exhibitors use lightweight extruded frames to create professional-looking displays that are easy to assemble and transport.

Lighting Diffusers for Signs

Backlit signs rely on diffusers to create uniform illumination. Fast food restaurants use extruded diffusers in drive-thru menu boards to maintain readability at all hours. Shopping malls rely on illuminated wayfinding signs with extruded acrylic diffusers to guide customers effectively. Airports integrate large-scale signage with customized diffusers that preserve clarity despite constant exposure to bright lighting conditions.

Mounting Channels

Mounting channels give signs secure attachment points and simplify installation. Retail chains use extruded channels to mount seasonal signage that changes frequently. Transit authorities integrate mounting channels in bus stop and subway signage to allow for quick updates. Stadiums and event venues rely on heavy-duty extruded mounting systems to install large LED boards safely and efficiently.

Partner with Lakeland Plastics for Tailored Plastic Extrusion Solutions

The applications of plastic extrusion are as varied as the industries that depend on them. From improving energy efficiency in construction to enabling advanced telecommunications infrastructure, extrusion provides the flexibility, durability, and cost-effectiveness needed to meet today’s challenges.

What makes extrusion even more powerful is the ability to customize solutions for highly specific requirements, whether that means creating a precise profile for a refrigeration gasket or engineering a unique lighting diffuser for an architectural project. Lakeland Plastics specializes in developing these custom solutions. We work closely with clients to understand their needs and deliver extruded components that exceed expectations.

With decades of expertise and advanced manufacturing capabilities, Lakeland Plastics has earned a reputation as a trusted partner across industries. If your business is seeking reliable, innovative extrusion solutions that support performance and growth, now is the time to connect with our team.

Contact us or request a quote today to explore how our tailored plastic extrusion capabilities can help your company succeed.

Construction & Building Applications

Construction & Building Applications Telecom Applications

Telecom Applications