Choosing how to manufacture a plastic part is a strategic decision that influences budget, lead time, quality, and long term performance. For many programs, the choice comes down to two proven methods: plastic extrusion and injection molding. Both can deliver outstanding results, yet they excel at different types of parts and business cases.

Plastic Extrusion: An Overview

Plastic extrusion is a continuous manufacturing process that creates parts with a constant cross section along their length. Dry resin pellets are fed from a hopper into a heated barrel. A rotating screw conveys and melts the material, then forces the molten plastic through a precision die that defines the profile shape. As the continuous profile exits the die, it is guided through a sizing station and cooled by air or water. A puller maintains consistent line speed, and downstream equipment cuts the profile to length, spools it, or performs secondary operations.

Because the profile is formed by pulling material through a die opening, extrusion excels at producing long lengths with repeatable dimensions. Common outputs include trims, channels, tubes, rods, gaskets, seals, glazing beads, wire raceways, lighting lenses, and many other custom profiles. Co-extrusion can combine multiple materials or colors in a single profile, such as a rigid body with a flexible seal, which makes extrusion a highly efficient way to integrate function while keeping tooling cost practical and setup times reasonable.

Injection Molding: An Overview

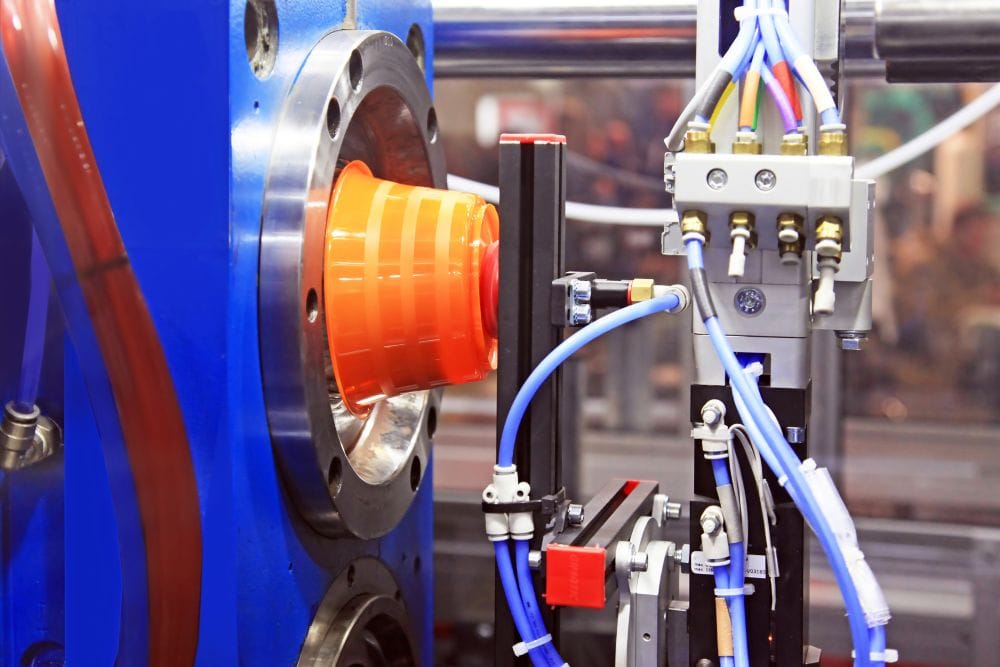

Injection molding is a cyclic process for producing discrete three dimensional parts. Resin pellets are heated and plasticized, then injected under pressure into a closed mold. The molten plastic fills the cavity, cools while held under pressure, and solidifies. Once the part reaches the required temperature, an ejection system pushes it from the mold and the cycle repeats. Molds can include multiple cavities to produce many parts per cycle.

Because the cavity defines all exterior and interior features, injection molding can create complex shapes with bosses, clips, snap fits, living hinges, ribs, and fine surface textures. The method is well suited for enclosures, housings, brackets, caps, connectors, and consumer or industrial components that require precise geometry and repeatable details. Tooling design is sophisticated and considers gate placement, cooling channels, venting, draft angles, and uniform wall thickness to control shrink and cycle time.

12 Key Differences Between Injection Molding & Plastic Extrusion

Making the right call here protects schedules and budgets. These key differences help determine how quickly you can launch, what you will pay per part, how parts perform in the field, and how easily you can scale or make changes later.

| Factor | Injection Molding | Plastic Extrusion |

|---|---|---|

| Core process | Cyclic melt injected into a closed mold | Continuous melt pushed through a shaped die |

| Geometry | Complex 3D shapes; discrete parts | Constant cross‑section; virtually any length |

| Typical outputs | Housings, brackets, caps, clips, connectors | Seals, trims, channels, tubes, lenses, raceways |

| Tooling cost | Higher; precision molds with cavities/cooling/ejection | Lower; dies are faster/cheaper to build |

| Lead time to first parts | Longer (tool build + sampling) | Shorter (often weeks) |

| Unit cost economics | Lowest unit cost at high volume; driven by cycle time and cavitation | Efficient at low–mid volumes; material per foot + line speed |

| Ideal volumes | Mid to very high | Low to mid; ongoing replenishment |

| Materials | Broad range, including filled/reinforced compounds | Broad range of rigid/flexible thermoplastics |

| Multi-material options | Overmolding, insert molding, multi‑shot | Co‑extrusion/tri‑extrusion (rigid + flexible, color stripes) |

| Tolerances and cosmetics | Tight across complex features; textures/gloss in tool | Consistent along length; finish via die/cooling |

| Scalability | Add cavities/presses; reduce cycle time | Increase line speed, add lines, longer runs |

| Secondary ops | Degating, light trim, assembly; automation optional | In‑line or offline punching, drilling, adhesive, printing, assembly |

| Part length | Limited by mold/press envelope | Cut to any length or spooled |

| Where complexity lives | Mold design (gating, cooling, venting, ejection) | Die design + melt/cooling + downstream sizing |

| Best for | Detailed 3D parts requiring integrated features | Linear profiles, seals, trims, protective covers, lenses |

1. Process

In plastic extrusion, material flows continuously through a heated barrel and a shaped die. The output is a never ending profile that can be cut at any length or spooled. Control levers include line speed, melt temperature, screw design, die design, and downstream sizing and cooling. Because the process never stops once running, extrusion favors long runs where consistency over length is required and startup scrap can be amortized effectively.

In injection molding, material is processed in cycles. Each cycle fills the mold, cools the part inside the tool, and ejects the finished piece. Control levers include injection speed, holding pressure, mold temperature, cooling time, and the number of cavities. Cycle time and cavitation drive output per hour. The process is optimized for discrete parts rather than continuous profiles.

2. Materials

Plastic extrusion runs a wide range of thermoplastics that perform well in continuous flow. These materials include rigid and flexible polyvinyl chloride (PVC), high-density polyethylene (HDPE), low-density polyethylene (LDPE), polypropylene (PP), acrylonitrile butadiene styrene (ABS), acrylic, polycarbonate, thermoplastic elastomer (TPE), and thermoplastic polyurethane (TPU). Material selection often emphasizes properties needed along the length of the profile such as flexibility for seals, clarity for lenses, or chemical and UV resistance for outdoor trims. Co-extrusion enables multi durometer profiles or color stripes without secondary assembly.

Injection molding supports many of the same base polymers, alongside filled and reinforced compounds for structural parts. Glass fiber-reinforced nylon, mineral-filled PP, and impact-modified ABS are common choices when stiffness, dimensional stability, or impact resistance is critical. Multi-shot molding and overmolding introduce multiple materials into a single discrete part, like a rigid substrate with a soft overmolded grip.

3. Costs

The plastic extrusion process typically requires a precision die and downstream tooling, which are faster and more economical to produce than a steel injection mold. For many custom profiles, die cost sits in an accessible range, and lead times are measured in weeks. Piece price is driven by material usage per foot, line speed, and yield, which makes extrusion cost efficient for medium to long lengths and steady ongoing demand.

Injection molding requires a machined mold with one or more cavities, cooling channels, and an ejection system. Tooling is a larger investment and lead times are longer. The payoff comes at scale. Once the mold is built, cycle time and cavitation can reduce piece price significantly for high annual volumes. However, if expected demand is uncertain or low, the upfront cost can be hard to justify compared to extrusion.

4. Return on Investment (ROI)

With lower tooling cost and quicker setup, plastic extrusion often reaches break even at lower to mid volumes. If your part is a linear profile and annual demand is moderate but steady, extrusion can deliver a favorable ROI because you avoid large capital tied up in tooling while still realizing competitive piece costs over time.

Injection molding ROI improves as volume climbs. The more shots a mold runs, the more the tooling cost is amortized. For parts with stable high demand and complex geometry that cannot be extruded, injection molding becomes the economical choice after the break even point by delivering very low unit cost and exceptional repeatability.

5. Scalability

Plastic extrusion scales by running faster line speeds, adding parallel lines, or scheduling longer runs. Changeovers are comparatively straightforward once a die is proven, so frequent replenishment is practical. Lead times can be short for repeat orders, especially when the die remains set up or when the same base material is used across stock keeping units (SKUs).

Injection molding scales by increasing cavitation, decreasing cycle time, or adding presses. Multi-cavity tools multiply output each cycle, and hot runner systems can reduce scrap and stabilize flow. While scaling can be powerful, it depends on capital availability and mold design tailored to the required capacity. Lead time is excellent once production is stable, but new tools or capacity expansions require planning.

6. Ideal Applications

Plastic extrusion is the natural fit for parts with a constant cross section. Applications include seals and gaskets for doors and windows, channels and trims for fixtures and displays, tubing and rod for industrial equipment, LED lighting lenses, cable covers, and weather stripping. These parts benefit from continuous production, long lengths, and material combinations along the profile.

Injection molding shines for discrete parts with complex geometry. Examples include housings, brackets, knobs, caps and closures, clips, gears, and components with internal features that require fully enclosed cavities. When the design requires detailed 3D forms or integrated features like threads or living hinges, molding is usually the only path.

7. Product Shape

The plastic extrusion process produces a profile that maintains the same cross section from end to end. The die opening defines the shape, and wall thickness is controlled around that geometry. You can vary length freely, and you can integrate hollows, multiple voids, or multi material regions within the profile, as long as the cross section is consistent.

Alternatively, injection molding produces discrete parts where every surface can be shaped by the mold cavity. You can create complex interiors, undercuts with slides, and features that vary across the part. Length is limited by mold size and press capacity, but shape freedom is much greater than in extrusion.

8. Versatility

Plastic extrusion offers co-extrusion and tri-extrusion for combining rigid and flexible materials, adding wear surfaces, integrating color coding, or embedding functional layers such as UV stable caps. Secondary operations like punching, drilling, adhesive application, embossing, printing, and assembly are readily integrated in line or performed offline to deliver ready to install components.

Injection molding offers overmolding, insert molding, and multi-shot techniques for combining materials and embedding metal inserts, threaded fasteners, or electronic components. Family molds can produce related parts in the same cycle. Surface textures and cosmetic finishes can be engineered into the tool for consistent appearance across large production runs.

9. Key Components

A plastic extrusion line centers on the screw and barrel that plasticize the resin. The die shapes the profile. A sizing table or vacuum tank stabilizes dimensions during cooling. Pullers control tension and speed. Cutters, saws, or winders complete the line. Success depends on tight integration of melt control, die design, and downstream handling.

An injection molding cell centers on the press and the mold. The mold base holds the cavity inserts, runners, gates, cooling channels, and ejection system. Hot runner systems maintain melt temperature inside the tool. Automation may de gate, trim, inspect, and package parts. Success depends on mold design that balances flow, cooling, and ejection for fast and stable cycles.

10. Equipment

Plastic extrusion equipment is modular and configured to the profile and material. Capital requirements are significant yet generally lower than fully equipped molding lines with complex tools. Tooling storage and maintenance are straightforward, and dies can often be modified or tuned to improve performance as the program matures.

Injection molding equipment includes the press, auxiliaries for drying and temperature control, and the mold itself. The mold is a precision asset that requires careful maintenance, periodic refurbishment, and dedicated storage. Changes to part design may require insert swaps or new tools, which adds cost and time.

11. Complexity

The complexity of plastic extrusion is in the die design, melt rheology, cooling, and downstream sizing. The process demands expertise to prevent issues like bowing, twist, or dimensional drift over long lengths. Once dialed in, it runs continuously with consistent results, which is ideal for steady demand.

Injection molding complexity concentrates in the mold. Gating, venting, draft, and cooling determine fill balance, cycle time, and dimensional stability. Process windows are often tight, and achieving cosmetic and dimensional targets at high cavitation requires sophisticated tooling and process control.

12. Benefits

Plastic extrusion delivers continuous lengths, efficient material use, quick changeovers, practical tooling costs, and excellent options for combining materials within a single profile. For applications where a constant cross section does the job, these benefits often translate into faster launches and lower total cost.

Injection molding offers advantages such as intricate shapes, fine details, excellent repeatability at high volumes, and the ability to integrate many features into one part. For applications that need complex geometry and large annual volumes, these strengths reduce assembly steps and unit costs.

Plastic Extrusion vs. Injection Molding: Which Manufacturing Process Is Right for You?

An informed decision starts with the fundamentals of your part and ends with a simple business case. Use the considerations below to move from concept to choice.

Geometry

If the part maintains a constant cross section along its entire length, plastic extrusion is usually the fastest and most economical path. The die defines the shape of that cross section, and the line produces continuous footage that can be cut to any length. Co-extrusion also allows rigid and flexible regions in the same profile, which can replace multi part assemblies.

When the design requires true 3D features—bosses, clips, living hinges, threads, internal cavities, or varying wall sections—look to injection molding. The mold cavity shapes every surface at once, enabling details that are not possible in a constant profile. If the part needs complex geometry and tight cosmetic control, molding is the right domain.

Volume & Demand Profile

The plastic extrusion process reaches break even at lower to mid volumes because tooling is practical and changeovers are efficient. It favors steady demand that repeats in batches or ongoing replenishment. Plastic extrusion also supports iterative development early in a program when minor profile tweaks are common.

Injection molding rewards high annual volume. The more cycles a mold runs, the more the tooling cost is amortized, which drives unit price down. If forecasts show large, stable demand over the life of the program, injection molding becomes increasingly attractive.

Tooling Budget & Timeline

Plastic extrusion dies are generally faster and less expensive to produce, with modifications and tuning achievable as a program matures. They help keep upfront capital modest and also shorten time to first article.

Injection molds are precision assets that require more time and investment. Multi-cavity tools, hot runners, and complex actions add capability and cost. The payoff comes later through low unit prices at scale, but the initial spend must align with budgets and stage gates.

Material & Performance Environment

Plastic extrusion supports a wide range of rigid and flexible thermoplastics, including options for UV stability, clarity, chemical resistance, and multi-durometer constructions. For seals, trims, lenses, and protective covers, this breadth allows tight tuning of function along the length of the profile.

Injection molding also runs broad material families and adds access to filled and reinforced compounds for structural parts. If the application demands high stiffness to weight, elevated heat deflection, or embedded inserts, molding materials and techniques may be the deciding factor.

Tolerances, Cosmetics, & Finishing

Extruded profiles hold consistent dimensions along length when die design and downstream sizing are dialed in. Surface finish is determined by material, die polish, and cooling. Secondary operations such as punching, drilling, printing, and adhesive application integrate well with extrusion lines.

Injection molding achieves repeatable dimensional control across complex features within the mold cavity. Cosmetic textures, gloss levels, and fine details can be engineered into the tool. Post processing often focuses on de-gating, light trimming, and assembly rather than in-line fabrication.

Lifecycle Cost & ROI Modeling

For plastic extrusion, the lifecycle model usually looks like modest tooling, quick validation, predictable material consumption per foot, and efficient replenishment. This profile often wins when launch speed and capital conservation matter.

For injection molding, the lifecycle model front loads cost into the tool and then benefits from low unit prices at scale. A simple break-even analysis that includes tooling amortization, scrap, and labor will show the volume at which molding surpasses extrusion for a given design.

Supply Chain, Flexibility, & Change Frequency

Extrusion programs are flexible. Dies can be changed quickly, and minor profile updates are feasible without replacing the entire tool. This characteristic is helpful when designs evolve or when SKUs share similar cross sections and materials.

Molding programs are stable once locked in. Changes to geometry may require insert swaps or new tooling. For parts with long life and minimal change, that stability is an advantage. For parts still evolving, consider whether extrusion can serve as a bridge to final form or as the long-term solution if the geometry allows.

FAQs About Injection Molding vs. Plastic Extrusion

A few questions come up in nearly every project. Use these answers to align your design, volume, and budget with the right manufacturing method.

What Is Plastic Extrusion?

Plastic extrusion is a continuous process that forces molten plastic through a shaped die to create profiles with a constant cross section. The profile is cooled, sized, and cut to length (or spooled). It’s ideal for trims, channels, tubes, seals, lenses, raceways, and other linear parts that benefit from uninterrupted length and consistent geometry.

What Is Injection Molding?

Injection molding is a cyclic process that injects molten plastic into a closed mold to form discrete parts with complex 3D features. After cooling in the mold, the part is ejected and the cycle repeats. It’s suited to housings, brackets, caps, connectors, and components with detailed geometry.

Is Plastic Extrusion the Same as Injection Molding?

No. Plastic extrusion produces continuous profiles defined by a die opening, while injection molding produces individual parts defined by a mold cavity. Extrusion excels when the cross section stays constant along the length; molding excels when the design requires 3D features that vary across the part.

Is Plastic Extrusion Cheaper Than Injection Molding?

It depends on geometry and volume. Plastic extrusion generally has lower tooling cost and shorter lead time, so it often reaches break even at lower to mid volumes. Injection molding requires higher tooling investment but delivers very low unit costs at high volumes. A simple ROI model that includes tooling, run speed or cycle time, scrap, and secondary operations will reveal the economics and ROI for your specific part.

Which Process Is Better for Long, Continuous Parts, Injection Molding or Plastic Extrusion?

Plastic extrusion. Because the process runs continuously, it can produce virtually any length and maintain a consistent cross section throughout. Parts can be cut to size, coiled, or spooled and later fabricated as needed.

Is Plastic Extrusion or Injection Molding Better for Complex 3D Geometry?

Injection molding. The mold cavity can form internal features, undercuts (with side actions), threads, ribs, bosses, and living hinges, all in a single cycle with excellent repeatability.

What Tolerances Can I Expect?

Extruded profiles hold tight, repeatable dimensions along length when the die and downstream sizing are tuned; tolerances depend on material, wall thickness, and profile complexity. Injection molded parts can achieve tight tolerances on complex features within the mold cavity, with cosmetic textures and gloss controlled by the tool surface. Your actual tolerances will be confirmed during design and sampling.

Can I Combine Materials or Add Soft Touch Features?

Yes. Plastic extrusion offers co-extrusion and tri-extrusion to combine rigid and flexible regions, add wear surfaces, or include color stripes. Injection molding offers overmolding, insert molding, and multi shot techniques to add soft touch grips, embed metal inserts, or integrate multiple plastics into one part.

What Are Typical Tooling Lead Times?

Extrusion dies are generally faster to build and modify, which helps accelerate first article runs. Injection molds take longer due to their complexity (cavities, cooling, ejection, and potential hot runner systems). Exact timelines depend on design complexity and capacity planning.

What Volumes Make Sense for Each Process?

Extrusion fits low to mid and ongoing replenishment volumes, especially when parts ship in long lengths or cut to size sticks. Injection molding makes the most sense at higher annual volumes where the tooling investment can be amortized across many parts.

Can Extruded Parts Be Post-Machined or Fabricated?

Yes. Punching, drilling, notching, stamping, printing, adhesive backing, heat forming, and light assembly are common with extruded profiles. Many of these can be integrated in line to reduce overall cost.

What Materials Can Be Used?

Both processes run a wide range of thermoplastics. Plastic extrusion commonly uses rigid and flexible PVC, PE (HDPE/LDPE), PP, ABS, acrylic, polycarbonate, TPE, and TPU; it’s frequently chosen for flexible seals, clear lenses, and protective trims. Injection molding also uses these materials and adds reinforced and filled compounds when higher stiffness, heat resistance, or dimensional stability is required.

How Do I Choose Between Extrusion & Injection Molding?

Start with geometry (constant cross-section vs. complex 3D), then check forecasted volume, tooling budget, and performance environment. From there, compare lifecycle cost and the likelihood of design changes. When in doubt, share your drawing or sketch. An engineering review will quickly clarify the best route for your program.

I Only Have a Sketch. Can You Help?

Yes. If your part is a profile, we can review a simple sketch with basic dimensions, environment, and volume assumptions. Our team will suggest materials, confirm manufacturability, and either provide you with a quote or advise if injection molding is the better path for your design.

Contact Lakeland Plastics: The Leading Plastic Extrusion Company

Both methods are proven and capable. Plastic extrusion excels when the part is a continuous profile with a constant cross section, practical tooling, short lead times, and flexible downstream customization; injection molding is ideal when the part requires complex 3D geometry and projected volume justifies a larger tooling investment. Knowing where your design sits on that spectrum connects technical reality with business goals.

At Lakeland Plastics, we provide the technology and expertise to bring plastic components to life and offer the strategic partnership necessary for long-term success.

Whether you’re designing a new product or looking to optimize an existing one, we’re here to help. Our team is ready to collaborate with you on custom extrusion solutions that meet your exact needs—from concept to completion.

Contact us or request a quote today to discuss your project and discover how our expertise can move your vision forward.